thanks outlaw

Hello Guest User,

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

carb info

Moderators: KeithZ1R, chrisu, paul doran, Taffus

-

outlaw

carb info

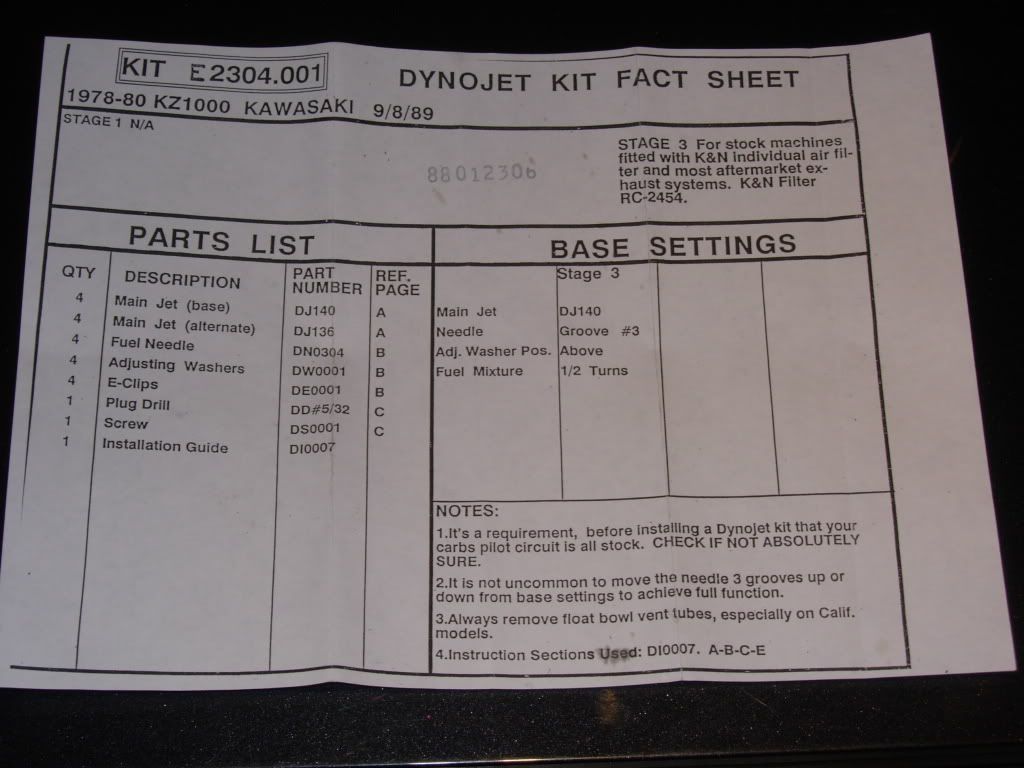

can any one please tell me if a stage 3 dyno kit is fitted, is it only the main jet,s that are changed in the carb? as i have a 4 in 2 one exhust fitted i have taken the pod filters off ( it was poping back through the filters ) the carb, and put a standard air box on, but at the moe it has 125 main jet,s fitted, ( when cold it is a bitch to run when warm it goes like stink you open the twist grip at 70 in top and it fly,s to 3 figers )would you think going to 115 would be best, at the moe under 2200/2500 rev,s when moving off it seem slugish,

thanks outlaw

thanks outlaw

- london calling

- Hardcore

- Posts: 3992

- Joined: 16th Apr 2004

- Location: Loughborough, East Midlands

- big green bus

- Custard Cream

- Posts: 962

- Joined: 2nd Apr 2006

- Location: durham

Hi John,

As bgb says, check for air correctors first (will be like little jets, screwed into the pilot airways).

If none fitted, you will need to open out the air screws.

Pick one of the air screws and turn it in until it (gently) seats, making sure you count how many turns ( you need to know where your starting from ) Turn screw back out to where it was and add half a turn more (out).

Then turn the the other air screws all the way in and adjust out to match the first one.

See if that improves the tickover, if it needs more increase by 1/4 turn at a time only.

Hope this helps.

As bgb says, check for air correctors first (will be like little jets, screwed into the pilot airways).

If none fitted, you will need to open out the air screws.

Pick one of the air screws and turn it in until it (gently) seats, making sure you count how many turns ( you need to know where your starting from ) Turn screw back out to where it was and add half a turn more (out).

Then turn the the other air screws all the way in and adjust out to match the first one.

See if that improves the tickover, if it needs more increase by 1/4 turn at a time only.

Hope this helps.

Some days I wake up Grumpy.

..................Some days, I just let her sleep.

..................Some days, I just let her sleep.

- Ginger Bear

- Hardcore

- Posts: 6850

- Joined: 16th Dec 2008

- Location: In the Dark.

- Contact:

Who is online

Users browsing this forum: No registered users and 19 guests