Hello Guest User,

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Pigfords OLD effort......now JULES NEW PROJECT!!!!!

Moderators: KeithZ1R, chrisu, paul doran, Taffus

- paul doran

- Area Rep.

- Posts: 15910

- Joined: 24th Sep 2004

- Location: near Dublin Ireland

- london calling

- Hardcore

- Posts: 3992

- Joined: 16th Apr 2004

- Location: Loughborough, East Midlands

- paul doran

- Area Rep.

- Posts: 15910

- Joined: 24th Sep 2004

- Location: near Dublin Ireland

Finished me ironing  so was allowed out in the garage for a hour or so...

so was allowed out in the garage for a hour or so...

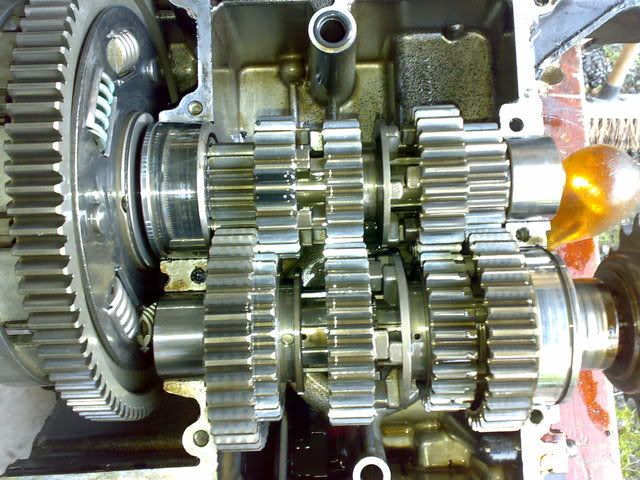

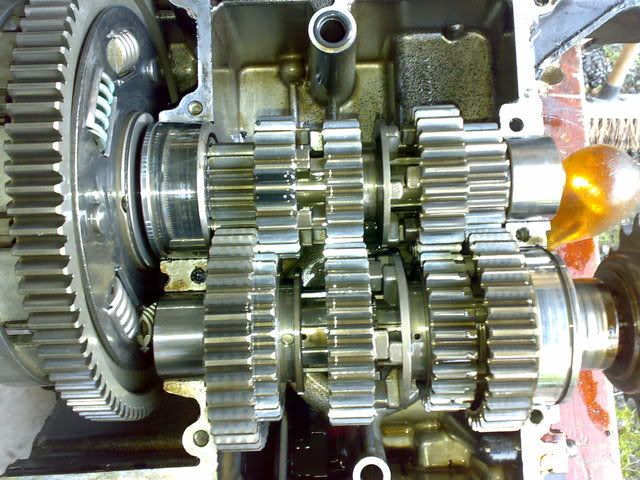

Split the cases....... had no chance of removing the clutch nut, it was well tight so decided to remove shaft & whack it in the vice....

so decided to remove shaft & whack it in the vice....

Took a good 10 mins persuasion with a 1/4" drive & extension bar....

The output shaft had a worn spline where the sprox fits so swapped with a good'n.

The oil pump mesh was a bit dirty, but have seen much worse...

Just need to clean casings & paint with me PJ1 Then its reassembly c/w new cam chain, oil seals & gaskets. be a few weeks time but got a bit of enthusiasm now

Then its reassembly c/w new cam chain, oil seals & gaskets. be a few weeks time but got a bit of enthusiasm now

Split the cases....... had no chance of removing the clutch nut, it was well tight

Took a good 10 mins persuasion with a 1/4" drive & extension bar....

The output shaft had a worn spline where the sprox fits so swapped with a good'n.

The oil pump mesh was a bit dirty, but have seen much worse...

Just need to clean casings & paint with me PJ1

And on the 7th day... Zeds were created!

Soft jawed vice......... Took me time & shifted it...

Tried it whilst engine in bike.... in gear, rear brake on & wheel locked....

All it did was strain the drive chain & cush drive and make the rear shox compress

No other option...... ain't got an air gun but all turned out OK in the end, no damage to gears...

but all turned out OK in the end, no damage to gears...

Tried it whilst engine in bike.... in gear, rear brake on & wheel locked....

All it did was strain the drive chain & cush drive and make the rear shox compress

No other option...... ain't got an air gun

And on the 7th day... Zeds were created!

tailiftchris wrote:I`ve got an electric impact gun from Snap On. Superb !

The problem can be torquing up when you`re all done though ?

I did have a hub tool for my LC, same as a TZ, was brill`.

I wonder if anyone has one for our Zeds ?

Chris, take an old steel clutch plate. Bend a piece of steel into an L shape (this will be the handle) weld the short end of the handle to the steel clutch plate and Bobs your uncle, one clutch hub holding tool.

If you do the welding yourself it will only cost a couple of quid. If you get it made locally I'd imagine it would cost upto about £20. Some people weld two plates together for extra strength but I've never had any problems with using one

Hopefully someone will post a pic or link to the type of thing I'm trying to describe.

tailiftchris wrote:Understand completely what your saying.......and an excellent idea !

Is it strong enough when your trying to torque up to 80ft/lb though ?

Chris, a lot of it depends on how much thought you put into the design but I've never had any probs. My most sturdy one made for a 750 turbo I had has the handle made out of steel bar approx 10 or 12ish mm diameter that is welded to the clutch plate in two places about 3 inches apart (picture a piece of bar approx 3' 6" long, bend it into a V shape with an internal angle of about 20 degrees then bend the 2 ends over so they are about 3 inches long and weld to the plate approx 3 inches apart).

Obviously the more plates you weld together the more the load will be spread across the hub reduceing the risk of damaging the hub when you apply the load.

If you want me to email you a pic let me know and I'll take the camera into the shed tomorrow.

The idea for this tool isn't one of my own. In fact I saw one advertised in the motorcycle press the other week with a RRP of £70. Make or get your own made though. A lot cheaper than £70

Hope this helps

-

HOPPA

75mm pistons

Hi, been a while. On those 75mm pistons, i have a set of 75mm Arias pistons i picked up for Eddie but was advised that the standard gpz1100 barrell , which i presume you are refering to at 1089, cannot be bored to 75mm , leaving the wall thickness too thin, what do you think, cheers Hoppa

Pasc wrote:Obviously the more plates you weld together the more the load will be spread across the hub reduceing the risk of damaging the hub when you apply the load.

In fact I saw one advertised in the motorcycle press the other week with a RRP of £70.

I`m not in the market for one just yet but after MaineKZ and Pigfords woes it occured to me that specialist tools are something the club might have ?

It can`t be too long before the world runs out of clutch hubs can it ?

Asphalt Cowboy

Phil Churchett award winner 2015

Phil Churchett award winner 2015

Who is online

Users browsing this forum: No registered users and 11 guests