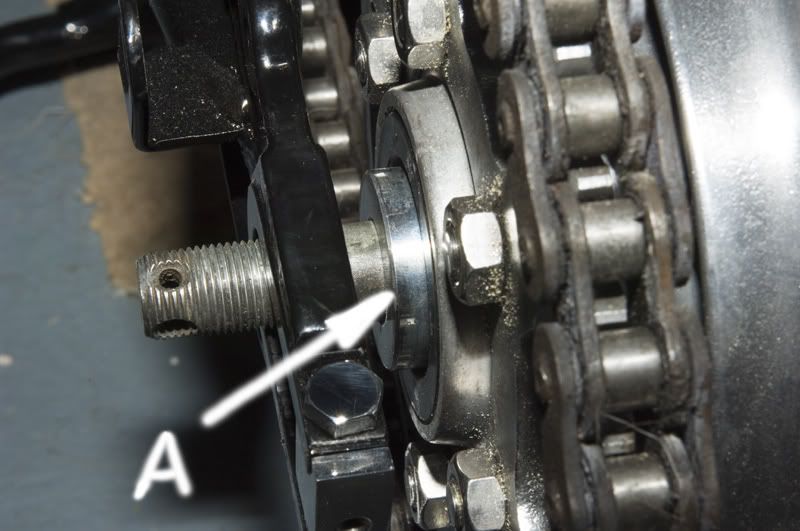

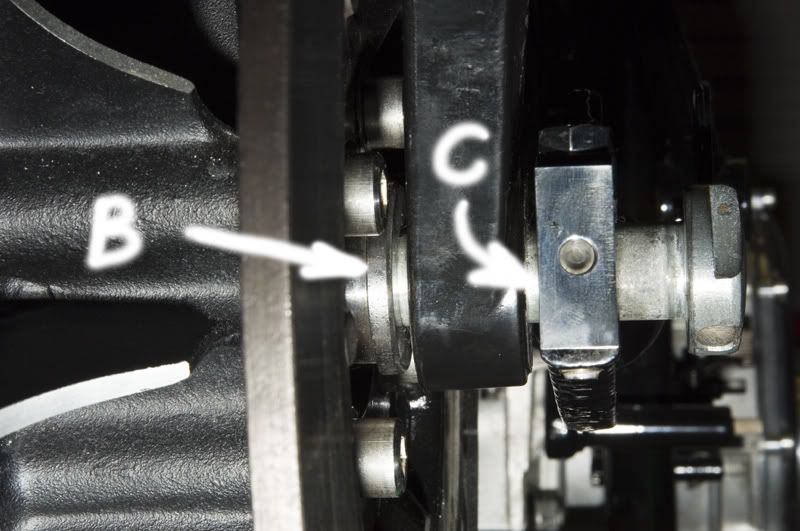

I am trying to fit a genuine kawasaki wheel into a genuine swing arm. The previous rear wheel was an Italian aftermarket job and the spacer/sleeve "A" in th photo is clearly not the right size as apart from anything else it doesn't fit snuggly into the grease seal. The 'top hat' spacer, "B" in the photo, may or may not be OK and I'm not sure whether there shoudl be some sort of spacer at "C". It does look as though there should be something. I know I haven't put the tensioners in but it is clear that something needs altering and I reckon that at least 5mm needs to be added to the sandwich. The workshop manual/parts book isn't very helpfully as the bike should have a spoked wheel.

I am pretty desperate to get this right. I have put the bottom end of the engine unit in and I would rather get the back wheel in. I've blagged some stainless bar to back whatever's required but I realsie that it is pretty critical that the wheel, disc and sprocket are in the correct place.

Can anyone please help with dimensions etc for these parts