Thanks zed1015 for info about valve seat being correct. I totally agree with your comments about valve timing being the most likely cause of the problem, however I can say that I studied this very carefully when I first disassembled the engine in Nov 2011. When I bought the bike in Nov 2011 I decided to strip the engine since it had not run for 10 years and was in a real mess. I noticed the piston/valve problem back in Nov 2011 and even went to the extent to buy a NOS exhaust sprocket so that I could be sure where the mark should be.

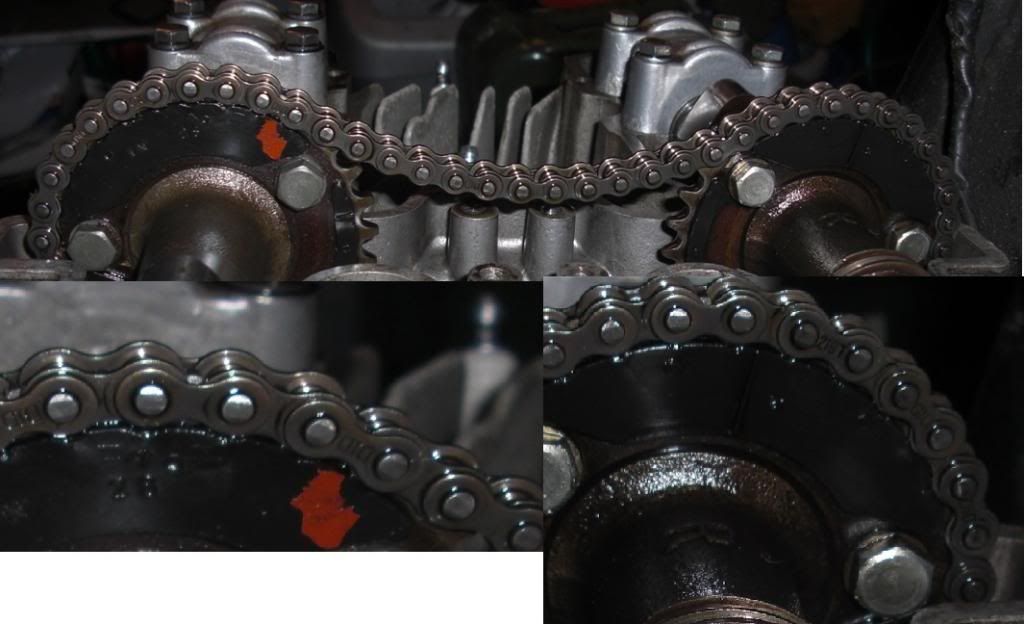

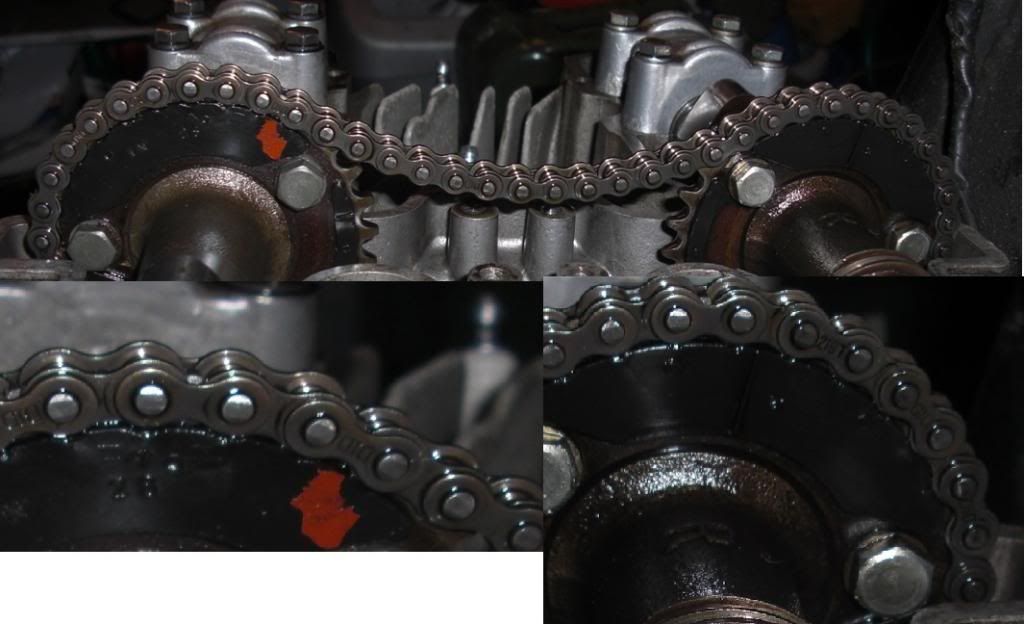

According to the Kawasaki Shop manual I have it shows that there should be 28 pins (to marker on inlet sprocket) after the pin that sits on the marker on exhaust sprocket. Attached is the original photo from Nov 2011 that would seem to show this being correct.

This is the setup as found in Nov 2011.

I've also attached a photo from the Nov 2011 disassembly that has the same marks on the piston crown from inlet valves. This appears identical to the current situation. (The previous owner would have done the timing at least 10 years previously.)

Piston crown during Nov 2011 disassembly.

As far as I can tell the inlet valves are not quite touching the piston because there are no marks on them, only a lack of carbon build up in the "close contact" area of the valves.

Attached is picture of inlet valve from current June 2013 disassembly.

As far as I can tell the timing has been set up correctly both times yet inlet valve to piston clearance is negligible.

I've just checked my notes with regards to the inlet camshaft dimensions and it shows the inlet bearing to be 24.47mm and cam height to be 36.33mm, thus giving a lift of 11.86mm. The bearing size and cam height seem to be correct according to the Z1 shop manual.

Any comments / suggestions more than welcome.