Help is urgently required. I've done this job before a couple of years ago. What I'm doing is changing the gearbox shaft and keeping the gears!

This is the shaft with the three - 3/16 balls.

How do I get those balls out... I have an idea I used to spin it?

Need to fix this this week-end.

RegardZ.

Hello Guest User,

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Z1 Gear-box Output shaft (Sprocket Shaft)

Moderators: KeithZ1R, chrisu, paul doran, Taffus

Z1 Gear-box Output shaft (Sprocket Shaft)

Garn (Sydney) Z1, Z1A, Z1B and Z900-A4

Once all the circlips, thrust washers and cogs are removed isn't the hole through which the balls were installed visible? I think this is the case.......though I could be wrong.

Dxyselia rlues, oaky.

http://www2.b3ta.com/youcantspell/

http://www2.b3ta.com/youcantspell/

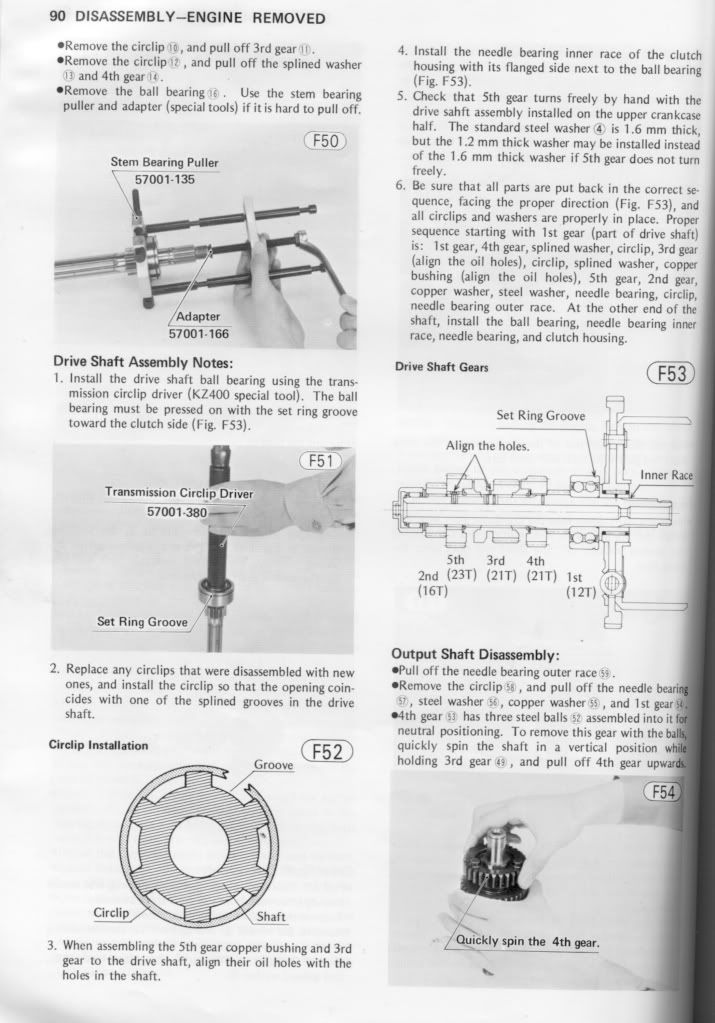

Thanks, for the reply George, I've looked at that hole and it does look as so it's part of the solution. However, I seem to remember just spinning the shaft allowing the balls to locate somewhere and "presto" the gear just slid off. All the manuals are vague in this area. One manual (Clymer~ Kawasaki Z1 early ed) says "Pull off 4th rear, turning the shaft as necessary to align the 3 steel balls".

Here's something... (Clymer ~ Kawasaki 1973-1980)

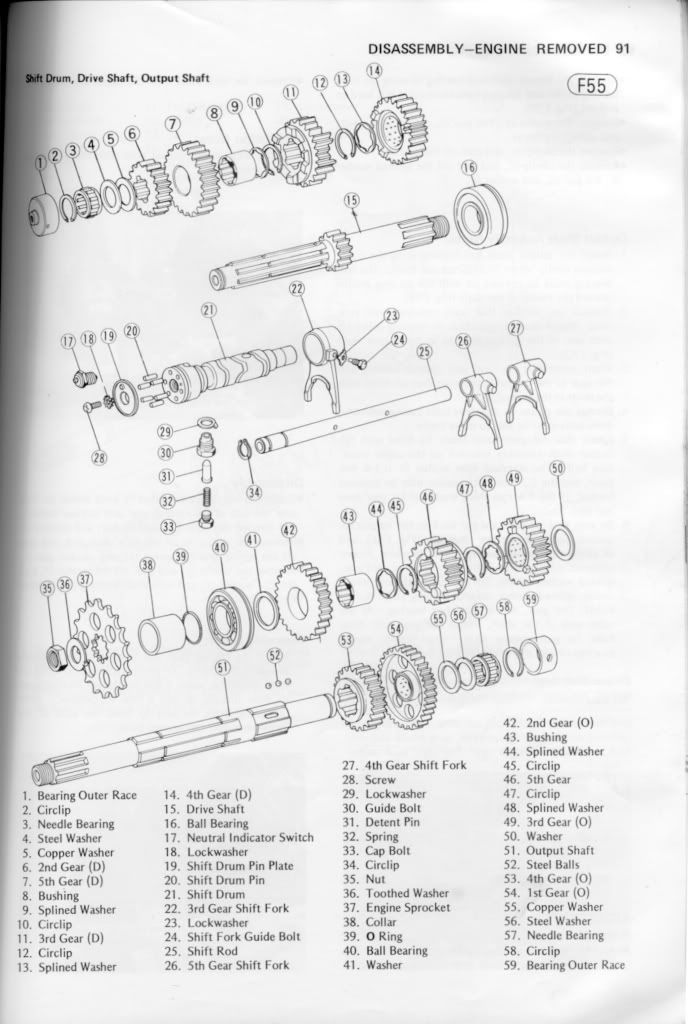

"Pull off 4th gear. To remove the gear, spin the shaft in a vertical position, holding onto 3rd gear. Pull the 4th gear up and off the shaft".

Maybe I should wash in petrol to remove any grease that may be hindering the balls from moving?

RegardZ.

Here's something... (Clymer ~ Kawasaki 1973-1980)

"Pull off 4th gear. To remove the gear, spin the shaft in a vertical position, holding onto 3rd gear. Pull the 4th gear up and off the shaft".

Maybe I should wash in petrol to remove any grease that may be hindering the balls from moving?

RegardZ.

Garn (Sydney) Z1, Z1A, Z1B and Z900-A4

Thanks for making me persist with this job.

I washed the muck out with petrol, gave it a spin and out she came.

Thanks again.... Incidently, those 3/16" dia holes are there so that the manufacture can drill thru to the other side to form a neat pocket for the ball which retreats to it when the gear is rotating.

Problem solved!

RegardZ

I washed the muck out with petrol, gave it a spin and out she came.

Thanks again.... Incidently, those 3/16" dia holes are there so that the manufacture can drill thru to the other side to form a neat pocket for the ball which retreats to it when the gear is rotating.

Problem solved!

RegardZ

Garn (Sydney) Z1, Z1A, Z1B and Z900-A4

PopsA1, You may have thought your contribution to my problem was too late.... It wasn't!

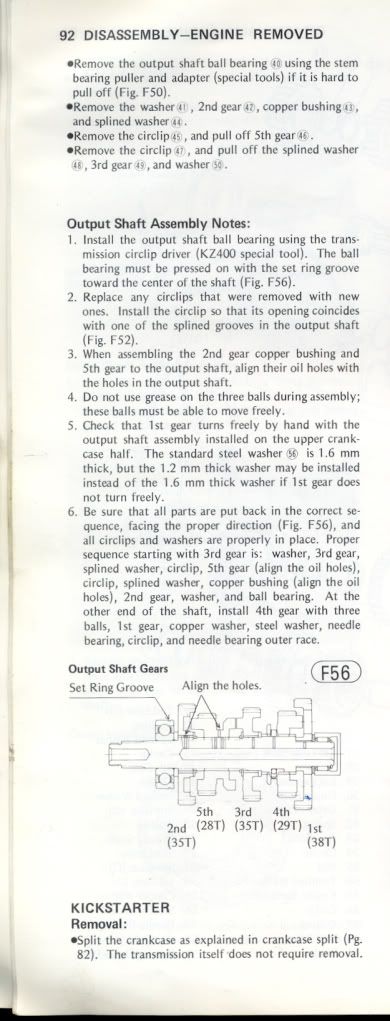

I read on the last page of your workshop manual, "Output Shaft Assembly Notes ~ Item 4", not to use grease on the balls when assembling. I had used grease on one ball, relying on gravity (in a horizomtal position) for the other two. I have since washed it out. Also, though not relevant this time, was Item 5, which talks about the two thincknesses of washers used in this assembly.

Thanks & regardZ.

I read on the last page of your workshop manual, "Output Shaft Assembly Notes ~ Item 4", not to use grease on the balls when assembling. I had used grease on one ball, relying on gravity (in a horizomtal position) for the other two. I have since washed it out. Also, though not relevant this time, was Item 5, which talks about the two thincknesses of washers used in this assembly.

Thanks & regardZ.

Garn (Sydney) Z1, Z1A, Z1B and Z900-A4

Who is online

Users browsing this forum: No registered users and 33 guests