Project Z900 A4 - Restoration - Pic Heavy

Posted: Tue Aug 12, 2014 12:49 pm

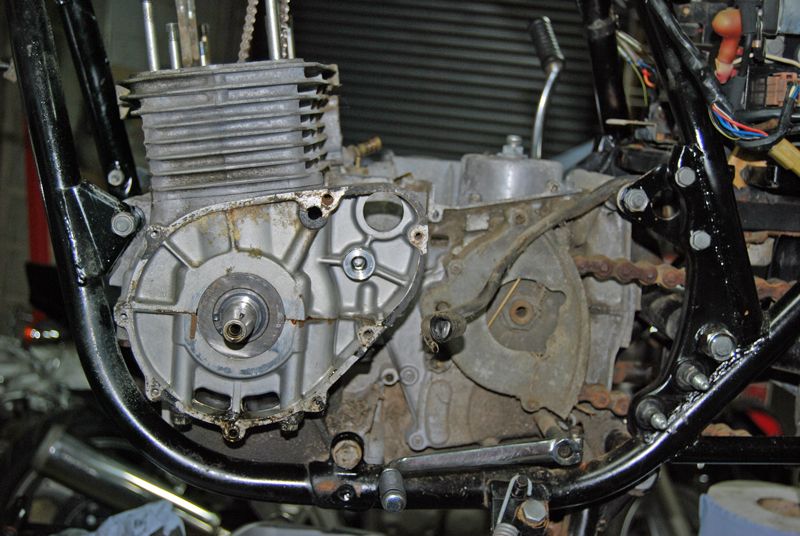

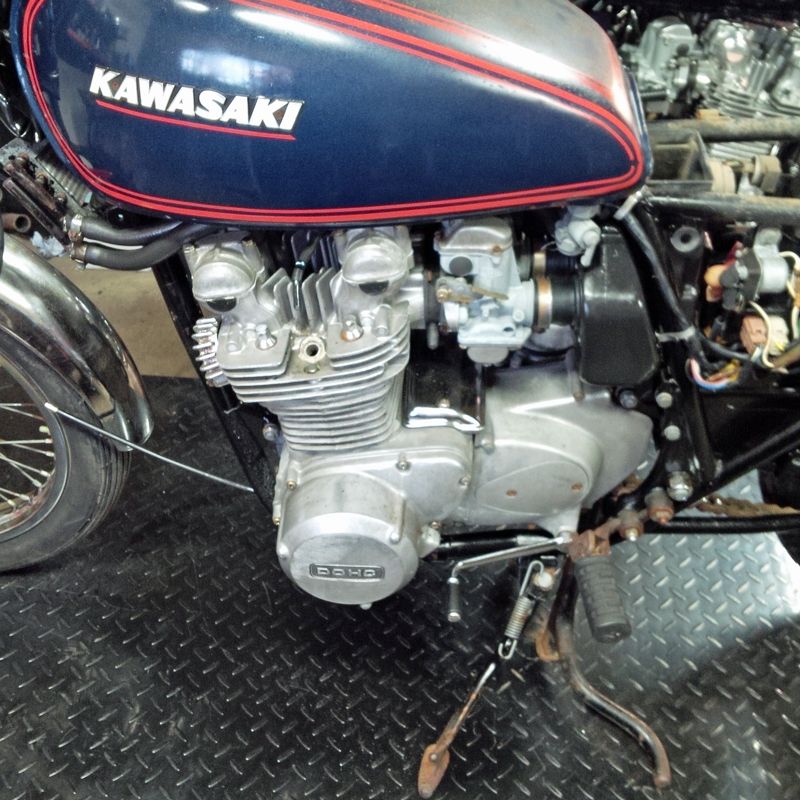

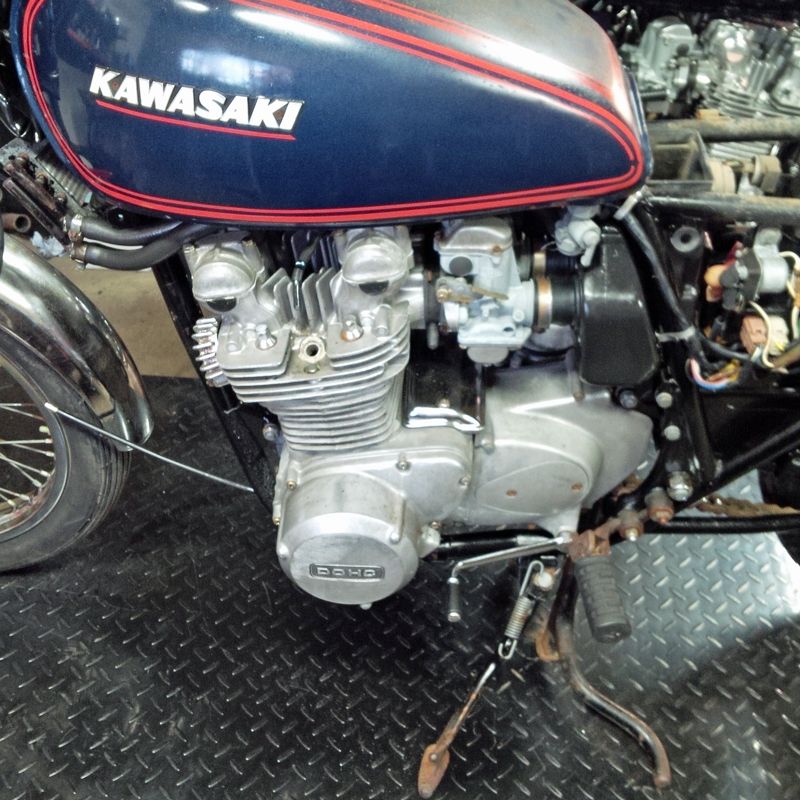

Not content with one Zed it's time for another to keep the Ltd company.

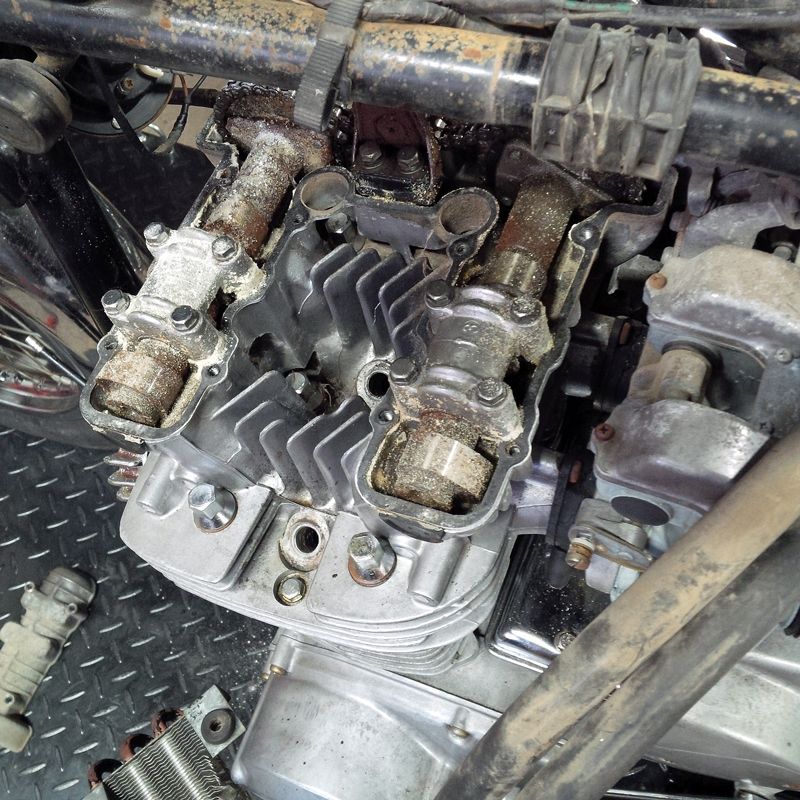

Picked up this little beauty - which does require a little attention.

Some investigation shows it's a June 1975 build.

It's always a tad worrying when there are no plugs in a motor that won't turn - but it was cheap.

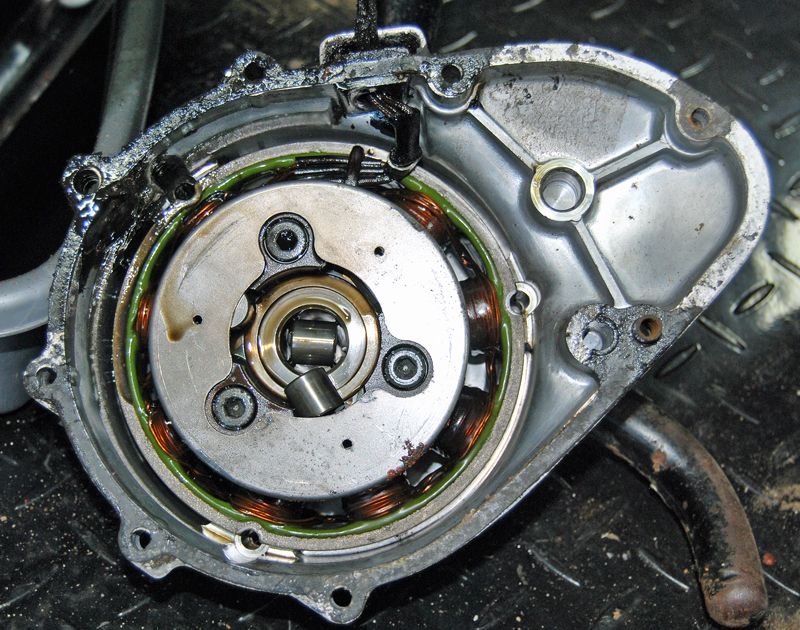

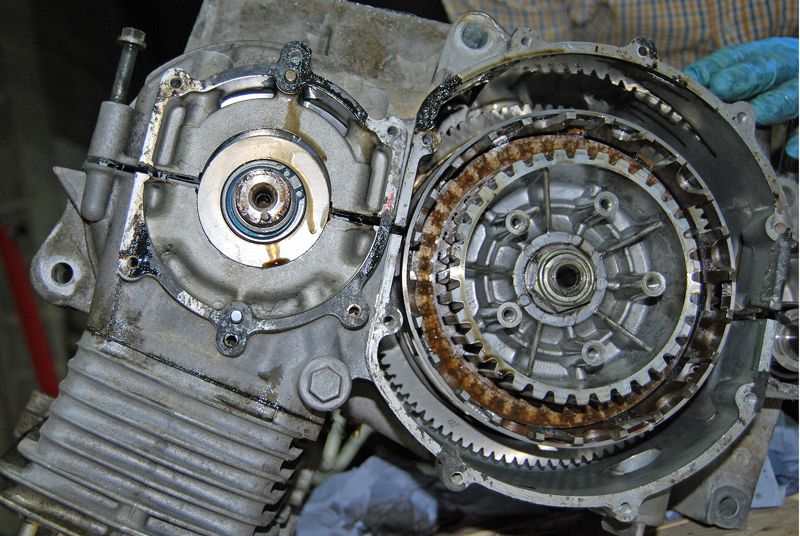

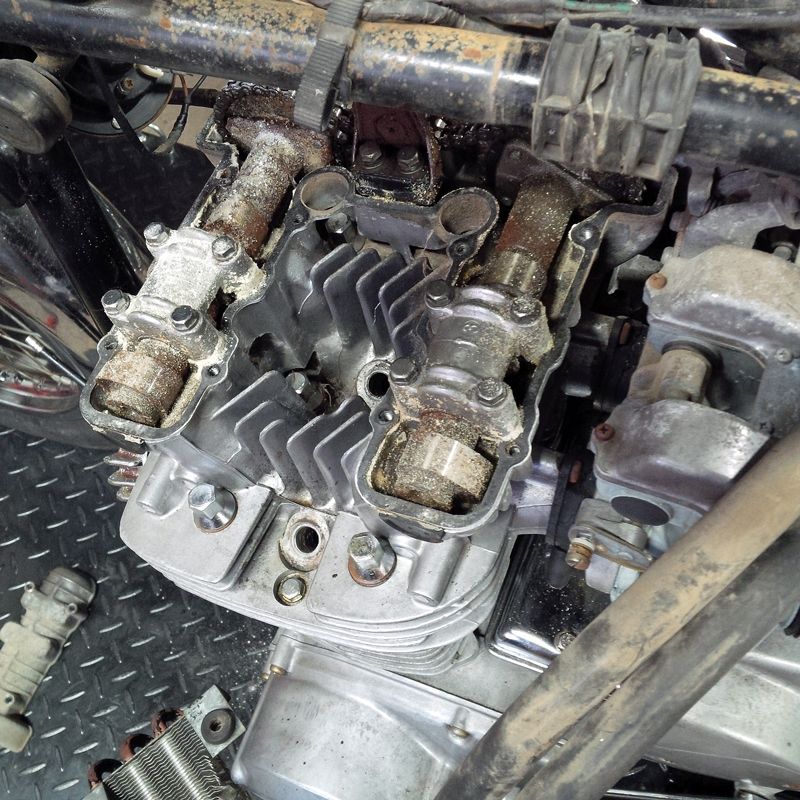

The motor was locked solid, cam cover off and what wasn't covered in corrosion was very clean and showed little sign of wear.

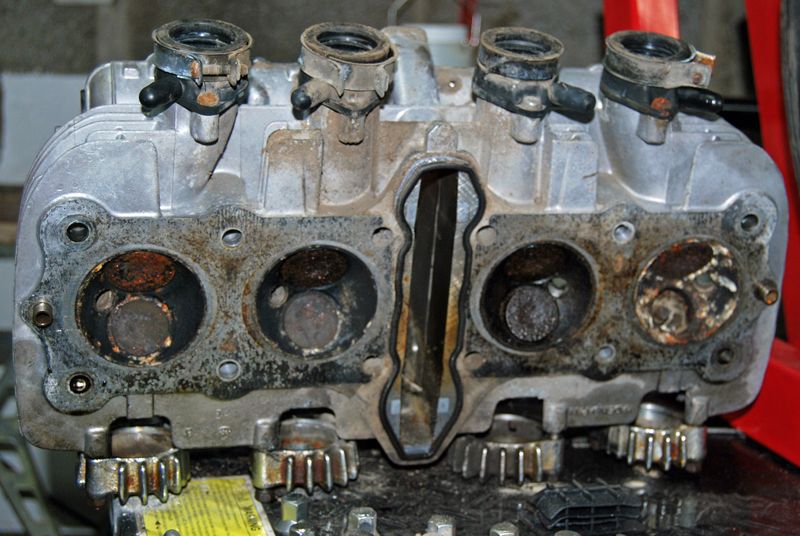

With the centre idler removed the inlet cam would turn - but the exhaust cam and crank were stuck fast.

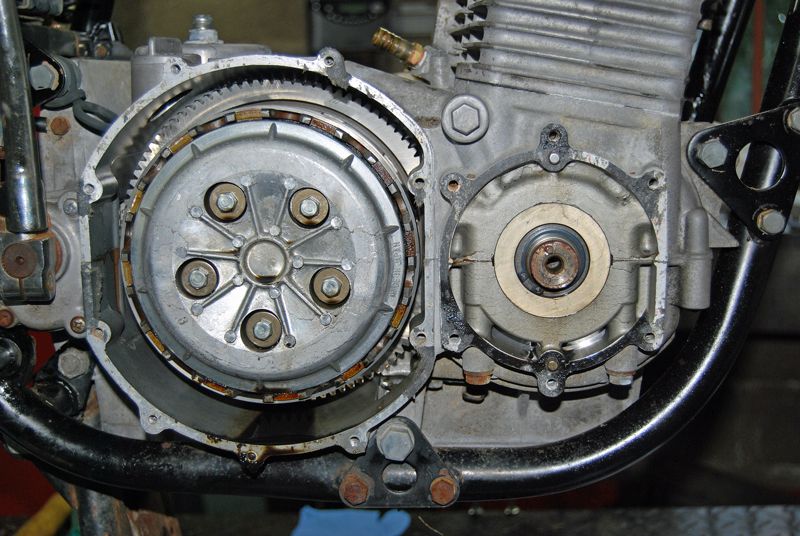

I think this is the reason the bike was retired from use, well you can't really miss it!!!!

Still won't turn though - Mmmm - pistons are at matched heights, soaking in plus-gas at this time as #3 bore was red rusty.

It was nice that every bolt on this motor was original and looked untouched, they all came undone without drama all the threads are clean, no helicoils this time nor any silicone gasket or loctite, even what was left of the oil was clean (ish).

I know these motors have a reputation for being tough - but I'm expecting at best a bent crank, I'm surprised the cam cap wasn't broken.

Going to take a while this one...

Such fun

Picked up this little beauty - which does require a little attention.

Some investigation shows it's a June 1975 build.

It's always a tad worrying when there are no plugs in a motor that won't turn - but it was cheap.

The motor was locked solid, cam cover off and what wasn't covered in corrosion was very clean and showed little sign of wear.

With the centre idler removed the inlet cam would turn - but the exhaust cam and crank were stuck fast.

I think this is the reason the bike was retired from use, well you can't really miss it!!!!

Still won't turn though - Mmmm - pistons are at matched heights, soaking in plus-gas at this time as #3 bore was red rusty.

It was nice that every bolt on this motor was original and looked untouched, they all came undone without drama all the threads are clean, no helicoils this time nor any silicone gasket or loctite, even what was left of the oil was clean (ish).

I know these motors have a reputation for being tough - but I'm expecting at best a bent crank, I'm surprised the cam cap wasn't broken.

Going to take a while this one...

Such fun