The bike so far:

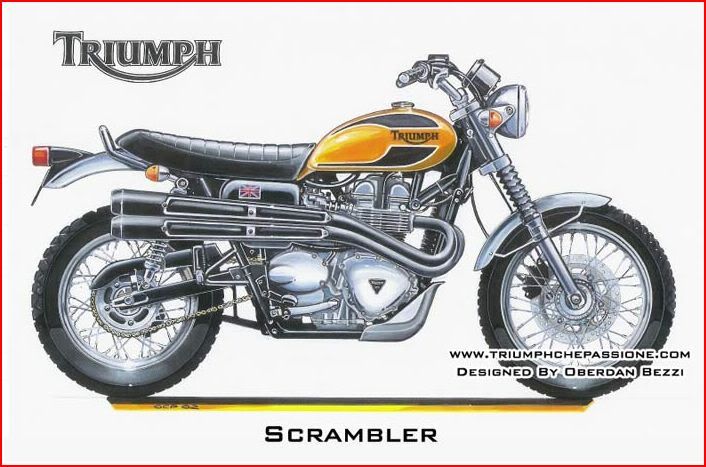

I started with a concept: something cool, timeless, practical and fitted me well. I just wanted it to be faster than a Bonneville.

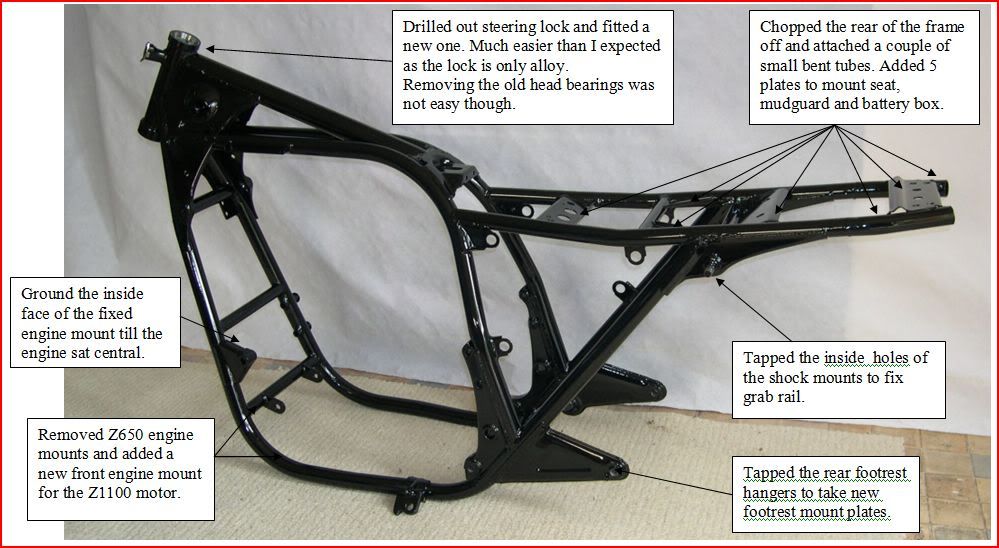

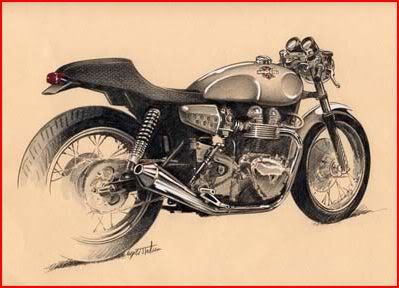

I worked out that the Z650 was a great starting point because its basic measurements are the same as a Bonneville.

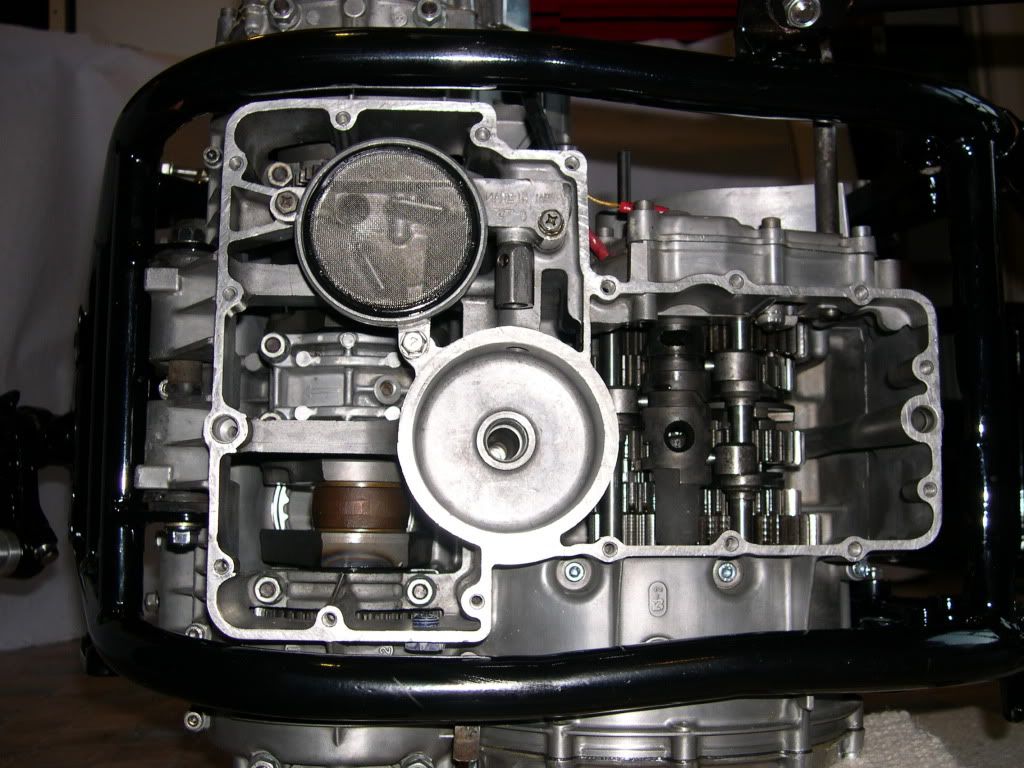

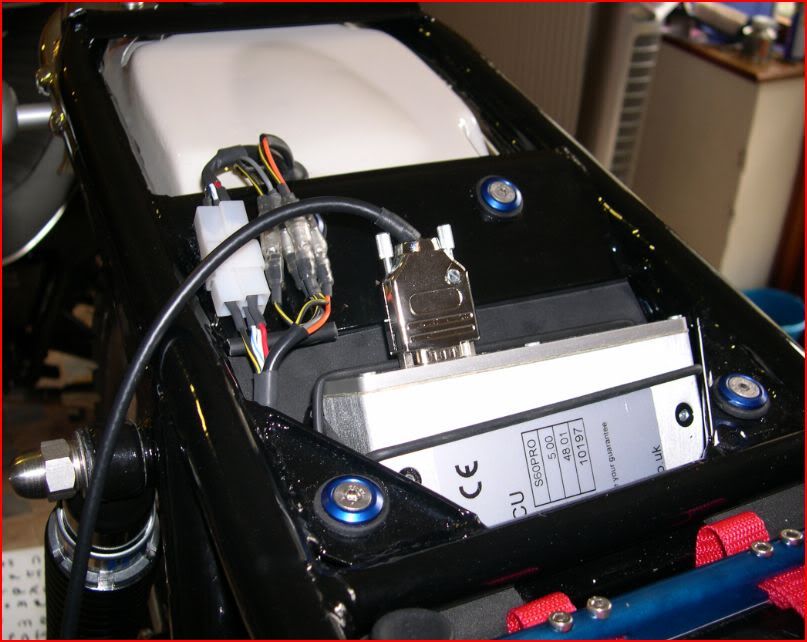

And I knew I could add the motor from my previous project-

I took the picture of a Z650 and using scissors and my scanner I made a junky picture of the bike I wanted.

My greatest lesson of this project is to start with the end point in mind. Don't start with a load of favourite bits and hope to make a coherent product at the end.

Start with the concept you want to achieve.

Like me you may be rubbish at drawing- but don’t let this stop you- there is enough technology out there to help you make an image of your dream.