Z1100ST Resto +

Posted: Sun Sep 18, 2011 2:37 pm

I got really into the RD250B resto, but then lost interest - probably because at the end of the day I'll never really ride it anywhere.

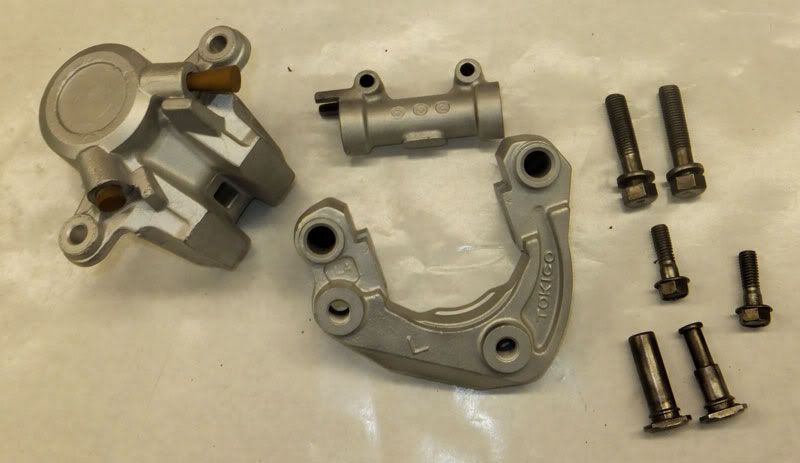

The Big eleven has been stuck at the back of the overflow garage for some while. I have been nagged by my conscience for a while that if nothing else I should at least take the calipers apart. The bike has been badly abused and it was very obvious that there was more water than brake fluid in the systems, and that if nothing else these should be striped.

I removed both front and back and brought them up to the workshop. I started on the front left caliper. Having removed the pads I was annoyed to find that it has those bloody filled in pistons, so I couldn't use my piston removal tool. The fluid that drained out when the banjo was removed proved my worst fear about it being powered by rusty water! With most calipers I can usually get the pistons out by forcing the air blower against the inlet hole, but this sucker was tight as a nun's flower.

What I needed was a tool I have often contemplated making - a tool to connect the air supply to the caliper without leaks and enabling me to have two free hands. Looking around for donor materials I found that the air shears had an over generous air lead I loped just over a foot off and then fitted another PCL plug to it. All I needed was an M10 x 1.25 pitch male thread to fit to the air lead. That seemed a tall order and the nearest I could find was a bit o brass hex stock. A bit of time on the cheap and nasty chinese lathe and hey presto:

I loped just over a foot off and then fitted another PCL plug to it. All I needed was an M10 x 1.25 pitch male thread to fit to the air lead. That seemed a tall order and the nearest I could find was a bit o brass hex stock. A bit of time on the cheap and nasty chinese lathe and hey presto:

Fitted the bit of air lead and I had a leak free, no hands required method of removing pistons. In the future I will need to add a control valve, but for the time being it works a treat.

The piston was pretty fecked and will have to be replaced. I can't find the bloody dremmel wire wheels, so I can't finish cleaning the seal grooves.

Had to heat the caliper with the hot air gun to get the bleed nipple out!

Next job is the mask up and bead blast the muckiness, ready for some two pack satin.

......

The Big eleven has been stuck at the back of the overflow garage for some while. I have been nagged by my conscience for a while that if nothing else I should at least take the calipers apart. The bike has been badly abused and it was very obvious that there was more water than brake fluid in the systems, and that if nothing else these should be striped.

I removed both front and back and brought them up to the workshop. I started on the front left caliper. Having removed the pads I was annoyed to find that it has those bloody filled in pistons, so I couldn't use my piston removal tool. The fluid that drained out when the banjo was removed proved my worst fear about it being powered by rusty water! With most calipers I can usually get the pistons out by forcing the air blower against the inlet hole, but this sucker was tight as a nun's flower.

What I needed was a tool I have often contemplated making - a tool to connect the air supply to the caliper without leaks and enabling me to have two free hands. Looking around for donor materials I found that the air shears had an over generous air lead

Fitted the bit of air lead and I had a leak free, no hands required method of removing pistons. In the future I will need to add a control valve, but for the time being it works a treat.

The piston was pretty fecked and will have to be replaced. I can't find the bloody dremmel wire wheels, so I can't finish cleaning the seal grooves.

Had to heat the caliper with the hot air gun to get the bleed nipple out!

Next job is the mask up and bead blast the muckiness, ready for some two pack satin.

......