Zed or dead?

Posted: Wed Jun 17, 2009 9:07 pm

Hi,

Long time since I have posted, but just starting to get round to doing work on the bike, idea was to run through the summer and and do more during the winter, but thought I'd start off doing the shims:

Em, ok, did a little bit more....painted the covers:

Thought shims would be simple enough job as the engine is out the bike, so out with the manual, gap should be 0.08-0.18mm, and the feeler guages...

First piston at TDC, camshaft sprockets aligned as specified, take the thinnest guage, 0.05, let the measuring commence.... :scratch: hmm, it doesn't fit and would seem to be completely closed up

Turn the engine over to each of the specified positions in turn.... same story...

Decided then to check for any gaps at any cam position over the buckets and found the following:

1: in .06 measured before the heel ex .06 before heel

2: in .08 measured after the heel ex no gap

3: in .09 on the heel ex .05 on the heel

4: in .06 measured before the heel ex .01 before heel

Anyone any idea what could cause this? Knackered cams/valves ?

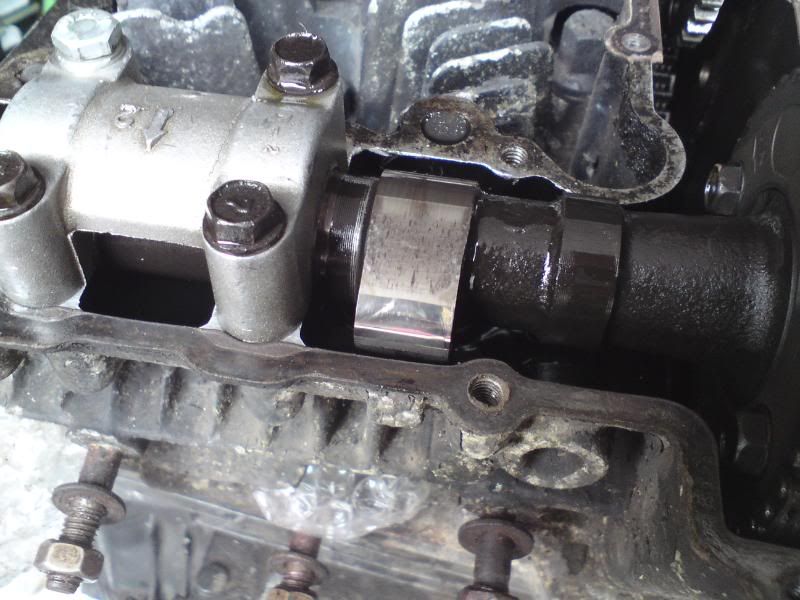

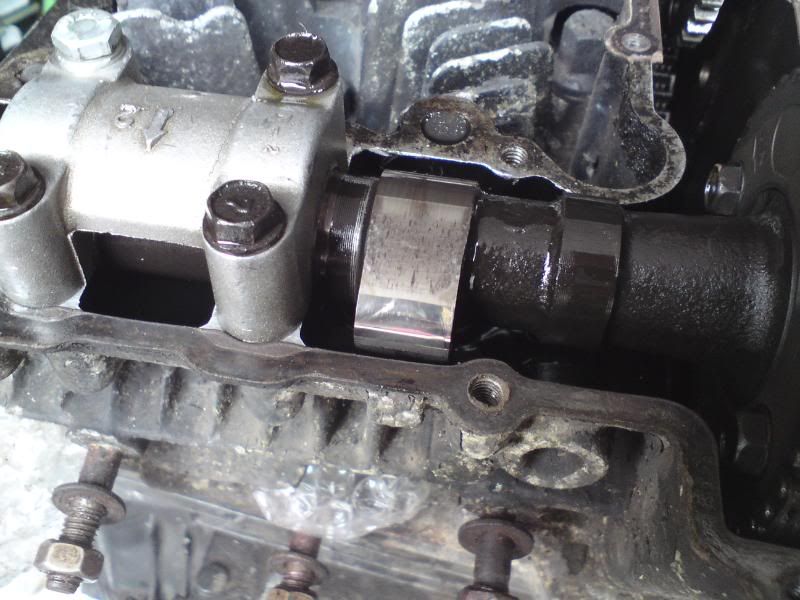

Here are some photos of the cams:

Similar story on most of the lobes, I was not the first to venture underneath the cam cover though, someone has been under there and having to fix things:

Over sized bolts here

Top left bolt was spinning and was a non-metric size, not the hairline fracture in the bracket, no doubt caused by pressures due to the loose bolt.

Anyway, decided that I would change the shims, see if I could get a bolt to fit the loose one, either by retapping or fitting a helicoil, or something - do not want to split the engine though.

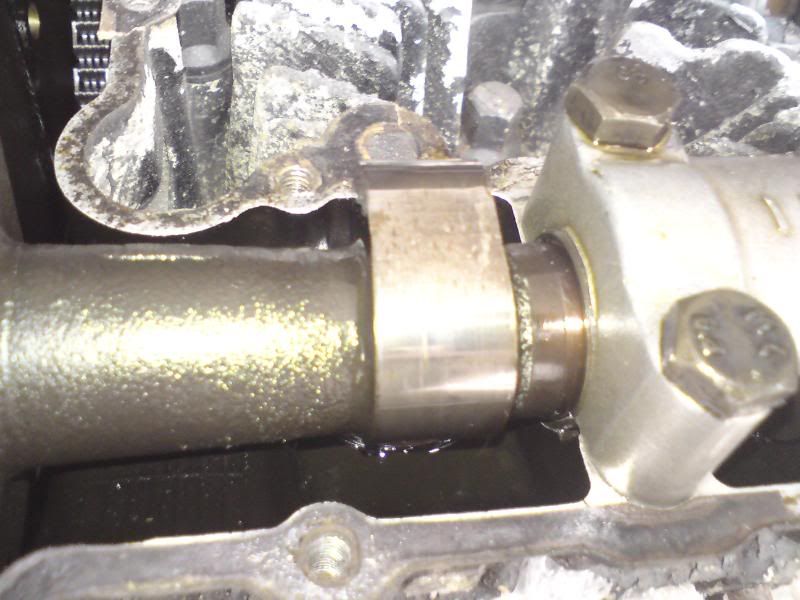

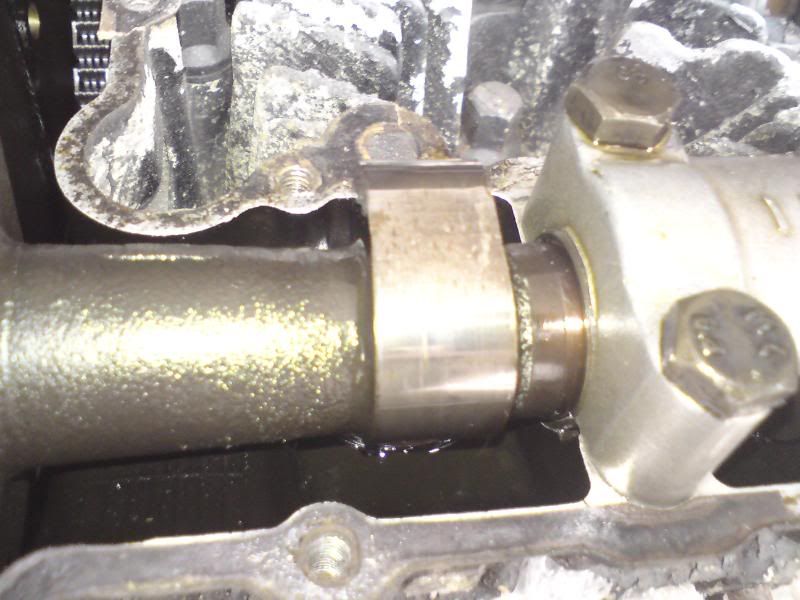

Cams out, bearing shells don't look too bad, though not great and some scoring on the camshaft:

Camshaft:

head shells

Net result, what do people think? Expensive fix, as in more exploration needed at the least and then its gasket set plus other bits?

Engine was running ok-ish before this, other than occasionally dropping a cylinder, but cleaned up coil contacts and stuff and that seemed to cure that issue, the only other annoying trait was petrol leaking out the carb inlets, even on the move, even once the carbs were cleaned and float heights and needle valves checked..though subsequent investigation found that one did stick occasionally.

Long time since I have posted, but just starting to get round to doing work on the bike, idea was to run through the summer and and do more during the winter, but thought I'd start off doing the shims:

Em, ok, did a little bit more....painted the covers:

Thought shims would be simple enough job as the engine is out the bike, so out with the manual, gap should be 0.08-0.18mm, and the feeler guages...

First piston at TDC, camshaft sprockets aligned as specified, take the thinnest guage, 0.05, let the measuring commence.... :scratch: hmm, it doesn't fit and would seem to be completely closed up

Turn the engine over to each of the specified positions in turn.... same story...

Decided then to check for any gaps at any cam position over the buckets and found the following:

1: in .06 measured before the heel ex .06 before heel

2: in .08 measured after the heel ex no gap

3: in .09 on the heel ex .05 on the heel

4: in .06 measured before the heel ex .01 before heel

Anyone any idea what could cause this? Knackered cams/valves ?

Here are some photos of the cams:

Similar story on most of the lobes, I was not the first to venture underneath the cam cover though, someone has been under there and having to fix things:

Over sized bolts here

Top left bolt was spinning and was a non-metric size, not the hairline fracture in the bracket, no doubt caused by pressures due to the loose bolt.

Anyway, decided that I would change the shims, see if I could get a bolt to fit the loose one, either by retapping or fitting a helicoil, or something - do not want to split the engine though.

Cams out, bearing shells don't look too bad, though not great and some scoring on the camshaft:

Camshaft:

head shells

Net result, what do people think? Expensive fix, as in more exploration needed at the least and then its gasket set plus other bits?

Engine was running ok-ish before this, other than occasionally dropping a cylinder, but cleaned up coil contacts and stuff and that seemed to cure that issue, the only other annoying trait was petrol leaking out the carb inlets, even on the move, even once the carbs were cleaned and float heights and needle valves checked..though subsequent investigation found that one did stick occasionally.