And you CAN do it - it's a heap more basic than you think.

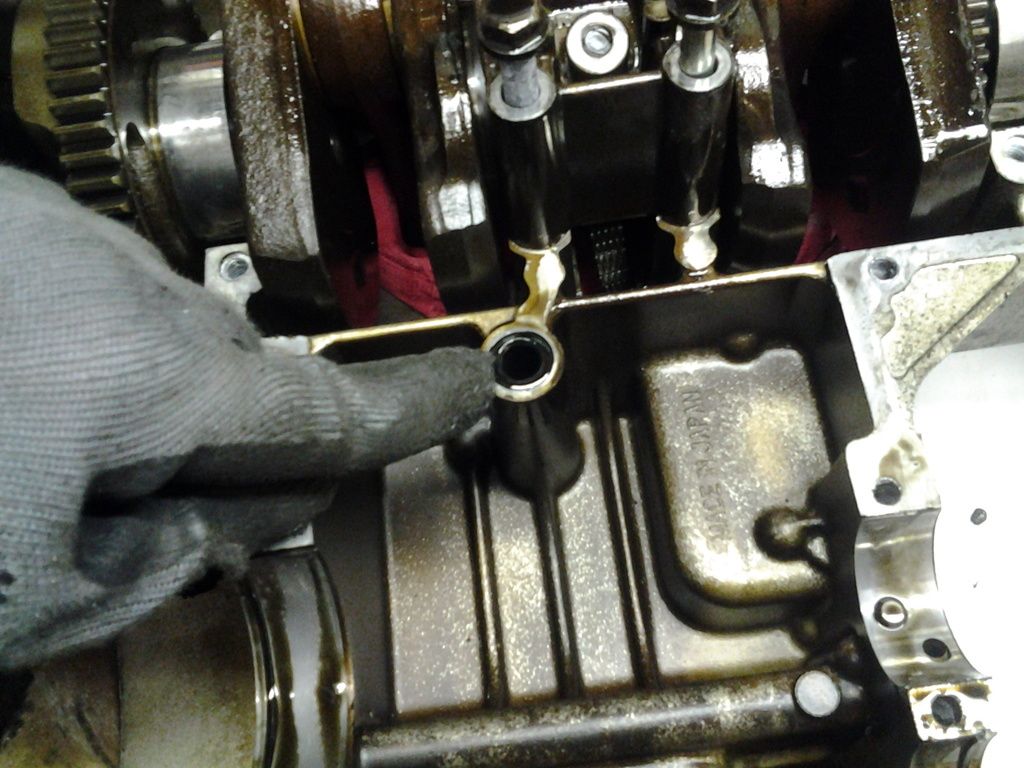

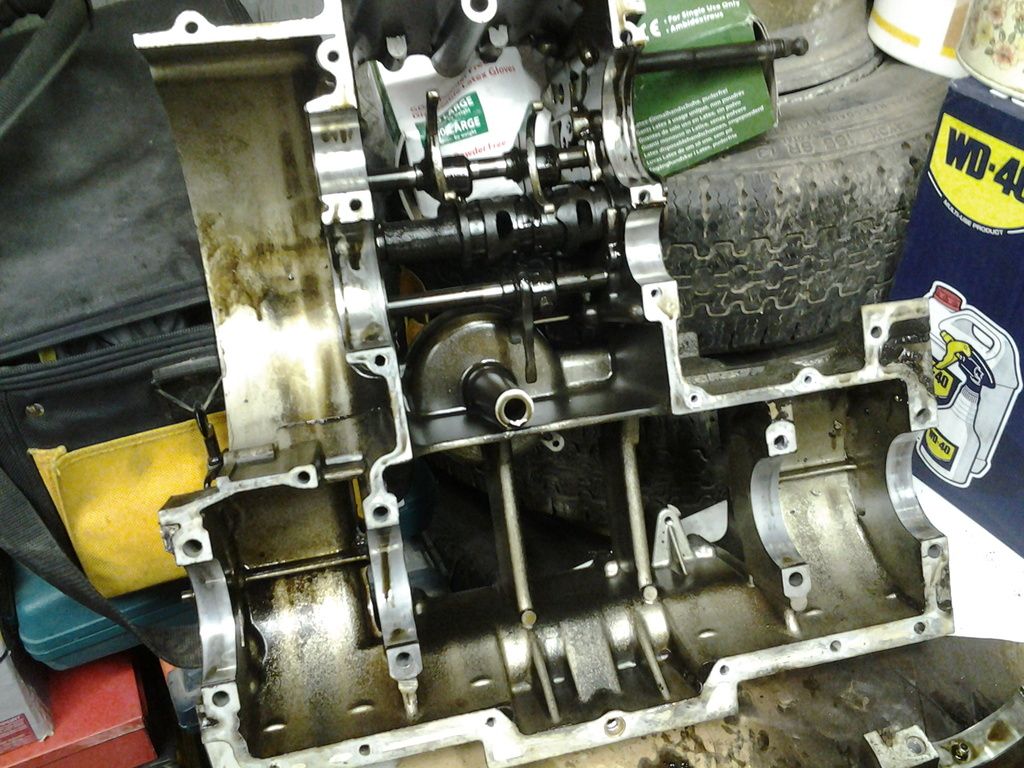

Take loads of pics - make notes each time you take something apart - which way round things go and in what order - note spring tension and direction - how things like cables or wiring is routed - it helps with learning which bit goes when and in what order and which way it faces when it's time to re-assemble.

Take note of the bolts as you remove them - they will be of differing lengths and diameters - some may have threadlock on - I draw a pic on some cardboard and make holes to take the bolts as I remove them, I mark the cardboard if they are loctited or have a washer etc.

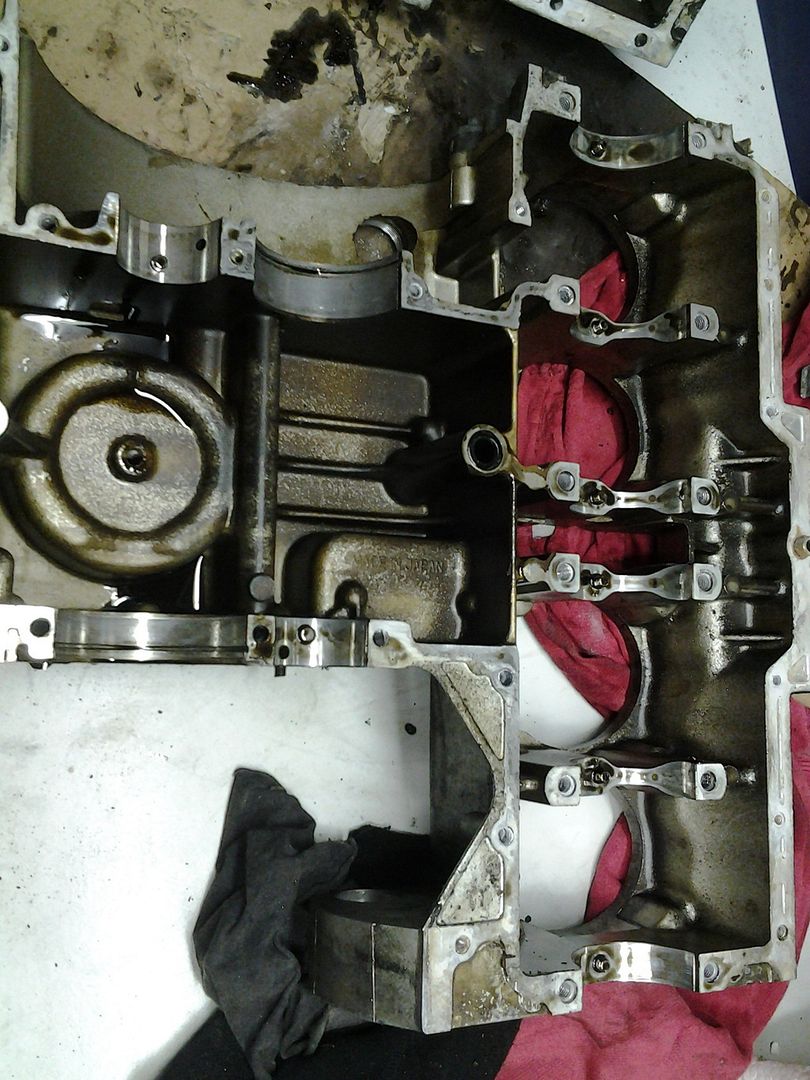

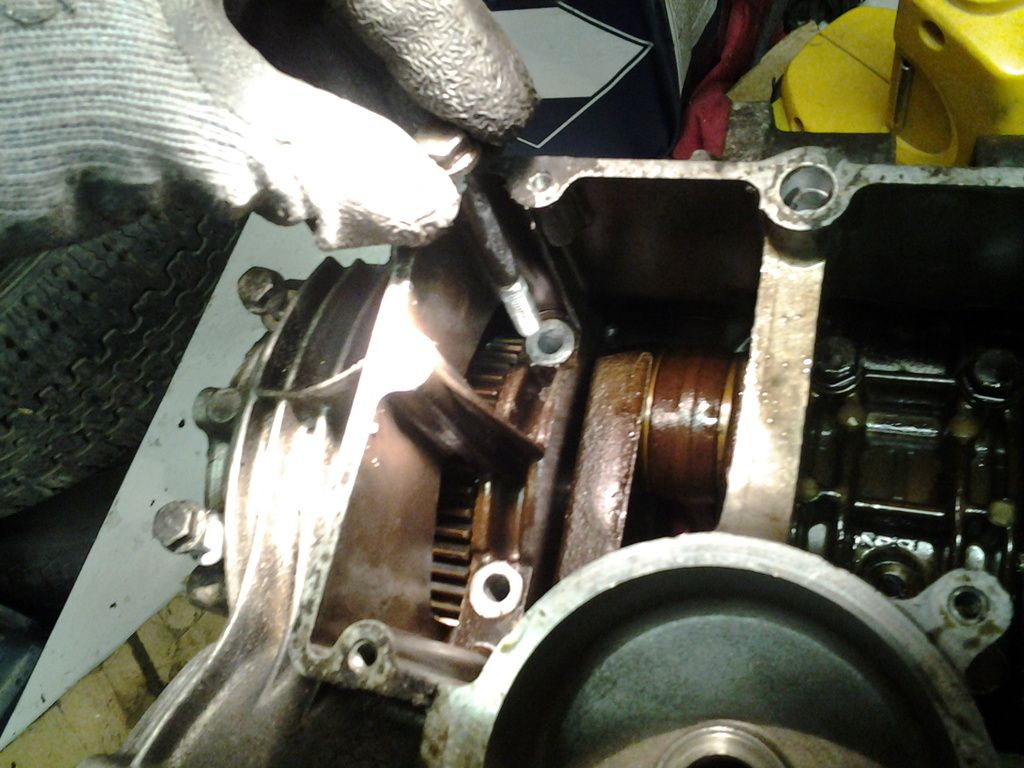

Keeping assemblies like gears together - stuff like that.

If you wake up in the night with a sudden realization you missed out the bearing or didn't torque up this bolt or that bolt - write it down and check later.

Thread check everything, lubricate every thread, torque every bolt.

In a perfect world doing a video would be best - but it's hard to hold the camera at the same time as spannering - plus it gets covered in oil and it catches all the swearing......

If you get stuck - do a search - or ask - I have found the combined knowledge on the forum to be truly amazing.

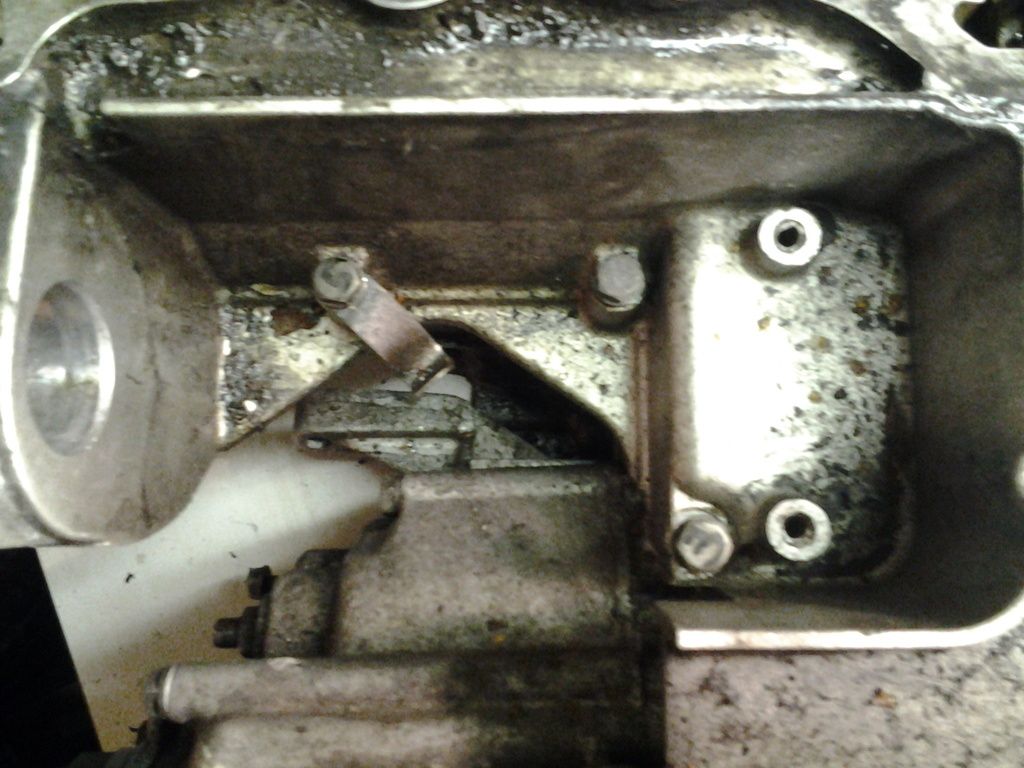

It may be frowned upon for obvious flammable reasons - but petrol works very well to get most of the surface gunge off, most of the cleaners available to us now are so namby pamby you could almost clean your teeth with them.

Following with interest - Good luck

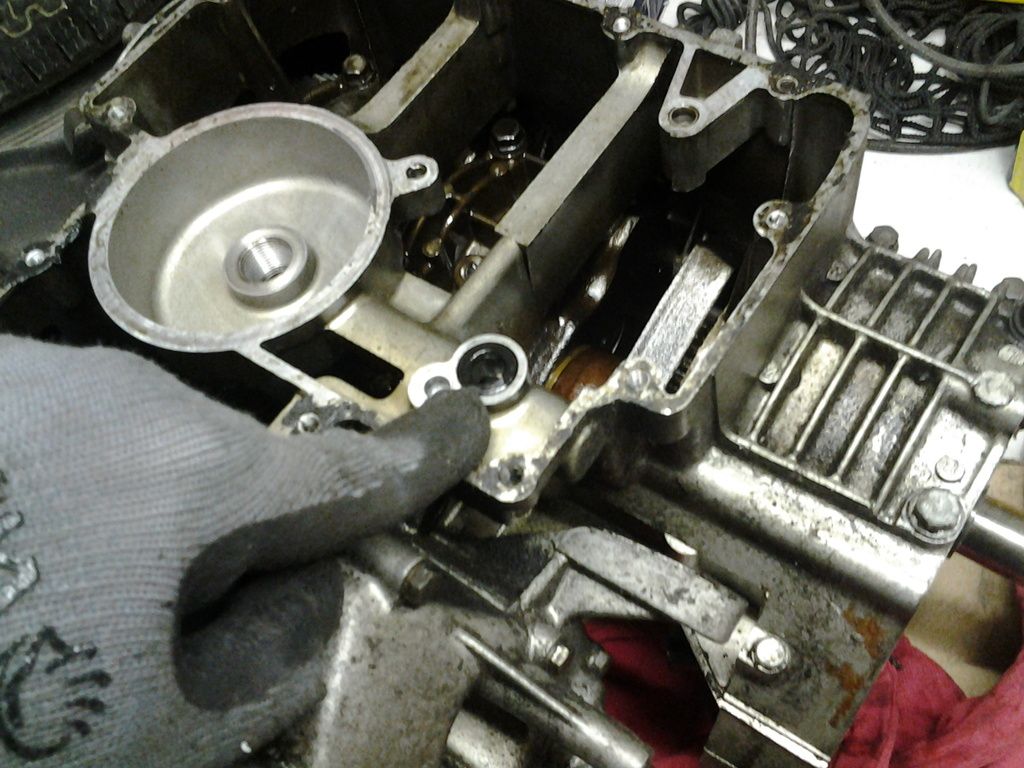

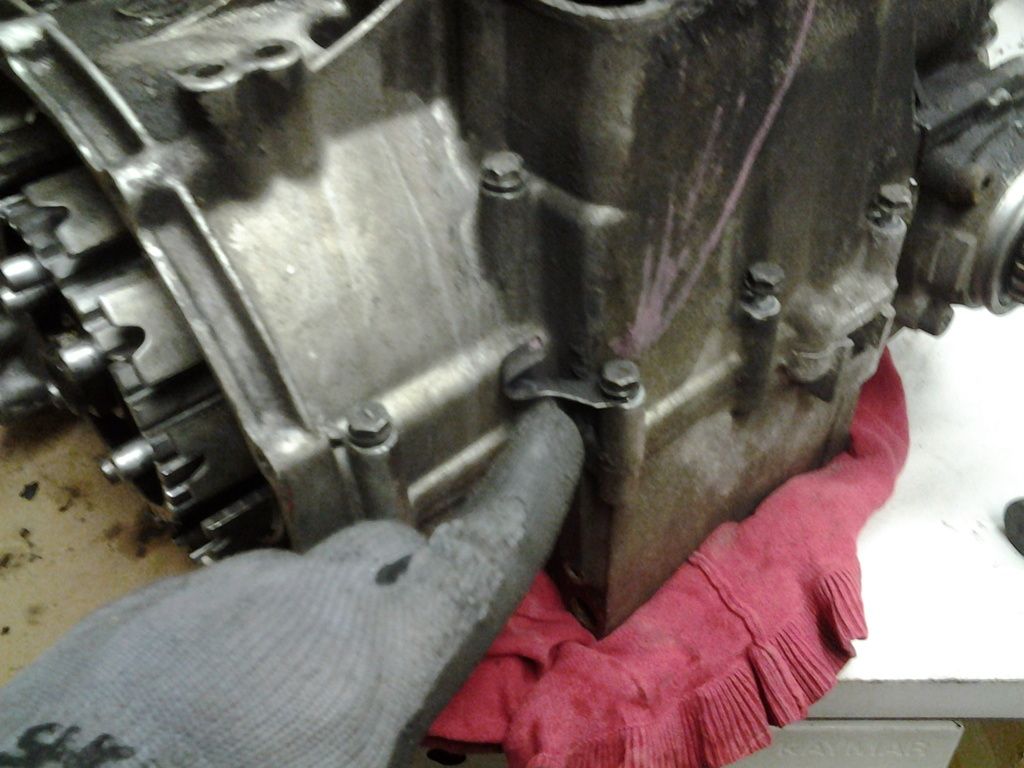

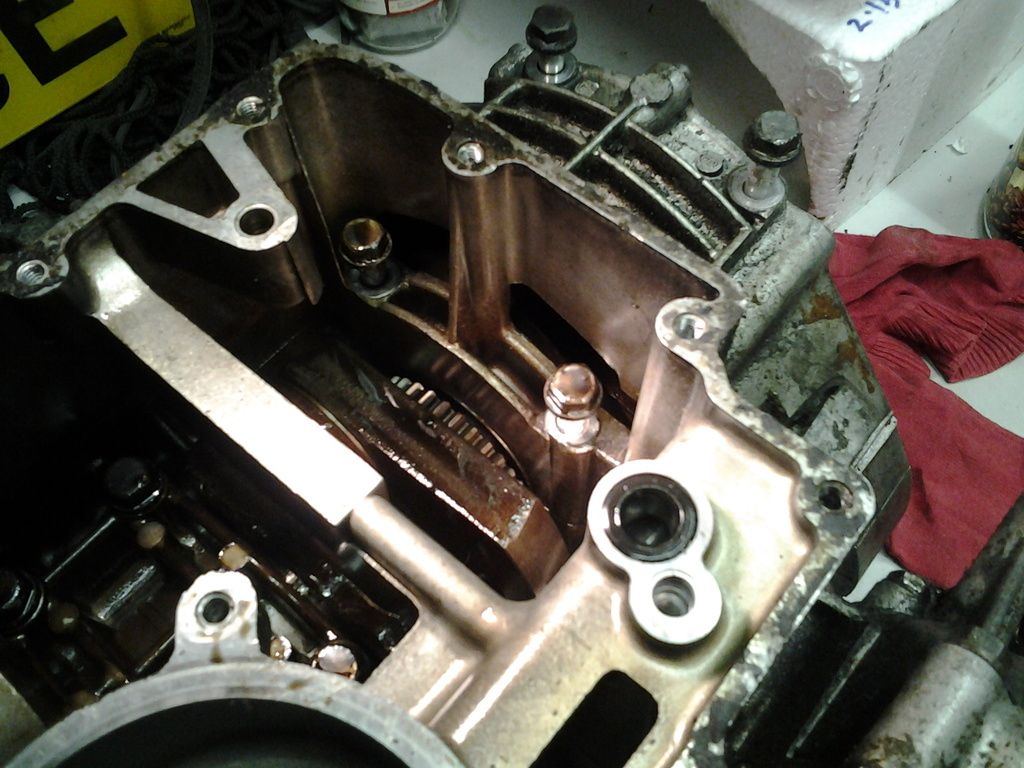

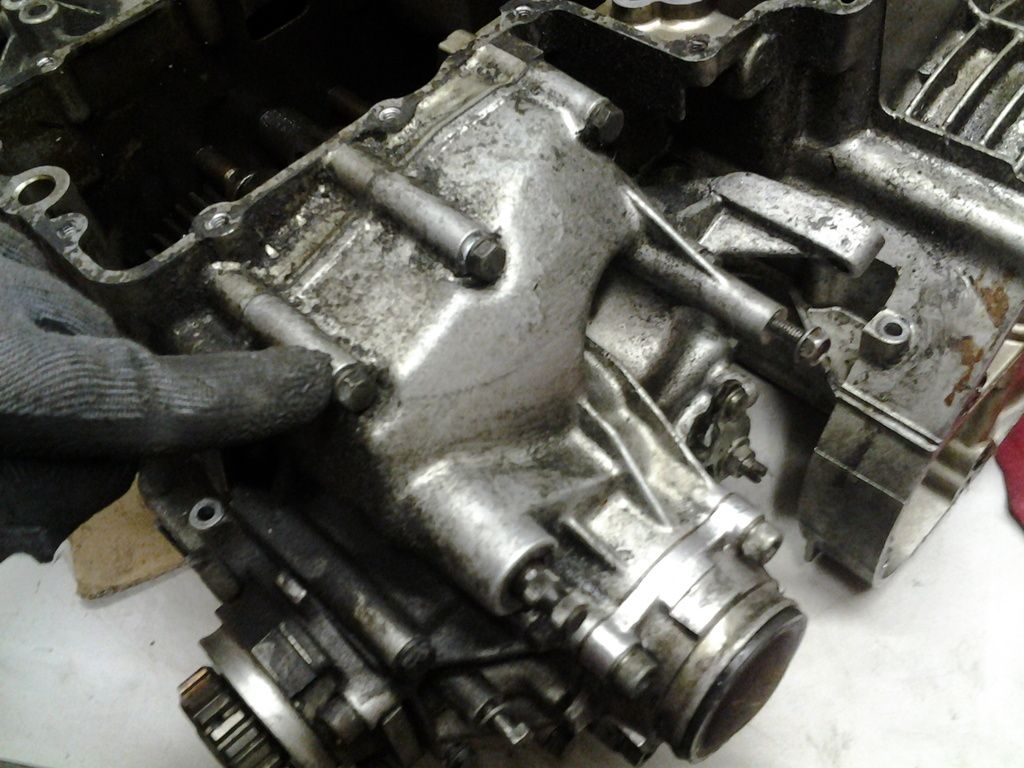

hooray, we're in

hooray, we're in