Fitted oil pump & sump with shiny new 'o' rings.

Went shopping....... Cheers Rob.

Results are really good.

Fitted one of these to the barrels............ Could hardly fit the old one.

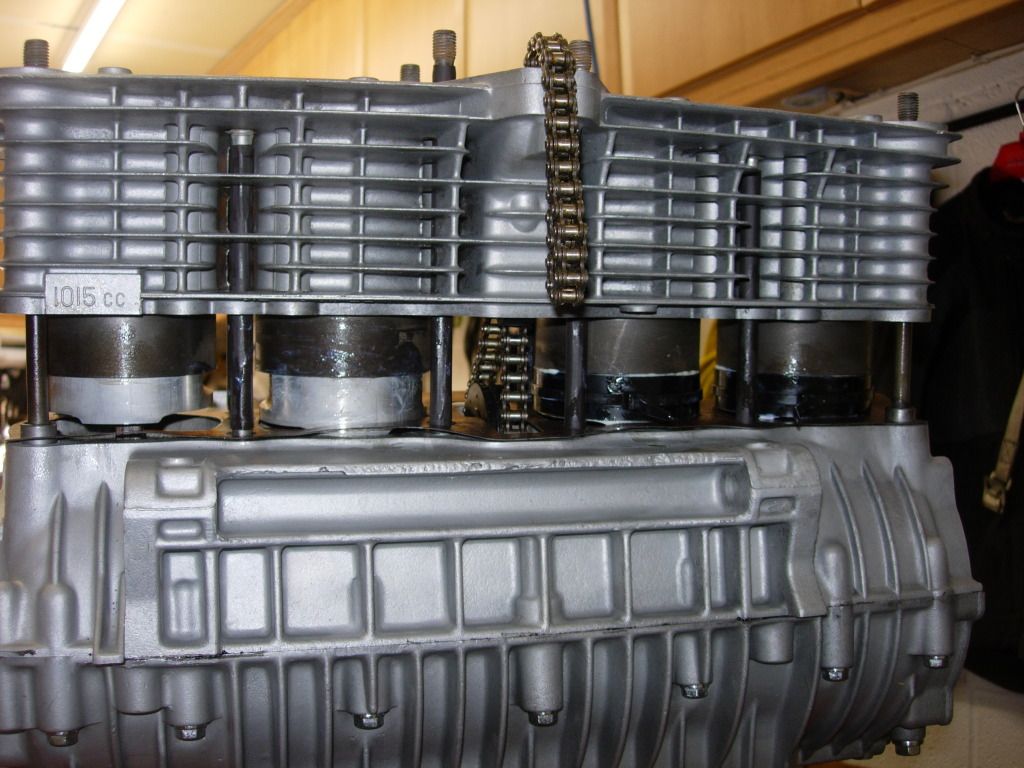

After trying to carefully fit the barrels with out any sort of ring compressor, I quickly realised it would probably end in disaster, so I cut up some trusty drainpipe & lubed it all liberally with Lubriplate No. 105 (Debbens) before cable tying the pipe tight. The bores hadn't been chamfered & this way made it a piece of piss to fit the barrels without causing any damage. Just think of it as an idiot proof method!

Next up was to fit the frame to the engine. Well I didn't plan to break into a sweat, so used the super lazy boy method of hoisting my frame over the motor.

Got a couple of engine mounts fitted, then rolled it upright & discovered this.

There was a bolt sheared off in there about 15mm below the top of the hole. I hadn't noticed this whist stripping the frame. It looks like someone had attempted to drill it out previously, just not centrally....... This is where my step backwards begins........ There are no pic's, oddly enough I didn't feel like sharing this little balls up.

I drilled through the old bolt, just fine with a 7mm drill bit, the problem came when I decided to try & tap it. Because the hole wasn't spot on, I think a piece of the original bolt, came loose & jammed the tap.

Upshot of all this is, the engine has come back out & the frame is with the local auto engineer having the bastard tap spark eroded, good news is, the process doesn't produce any heat. bad news is he couldn't guarantee he wouldn't mark the frame trying to squeeze it onto his machine.

With a bit of luck I might have it back tomorrow.

Lesson learn't there!!

Lesson learn't there!!