At the weekend I decided to play with my new chemistry set

At minor injury to my personal wealth I invested in a Zinc Plating kit from Gateros plating. I was aware before I started that it wasn't going to be worth it from financial saving, but I do love a new toy and I get a real kick out of doing stuff most people can't.

I have to say that when I started reading the ingredients of some of the bottles and bags I was quite shocked. Now I'm no chemist, and I am not well known for my rigid adherence to matters health and safety, but even I know that some of these chemicals are properly nasty. Oddly the passivates seems to contain the worst 'nasties' Nitric Acid, Sulphuric Acid, Chromium Trioxide and Hydrofluoric Acid. I had heard of most of these, but Hydrofluoric is a mega poisonous one. I remember someone on a sailing forum suggesting it's use for something or other and a chap with some proper knowledge of chemistry was horrified explaining to us that it was mamouthly poisonous and should only be handled by people who really understand the dangers. I decided to do the passivating bit outside

In the data sheet it actually says"Absorption through the skin may be fatal"

Even though I bought the deluxe kit, it still was missing a few bit eg Caustic Soda and distilled water for the electrolyte; but neither were expensive and were readily available. I used a slightly larger bucket for the electrolyte because I had to make room for the tank heater and the bubbler. I used one of the buckets that the glass beads come in from Machine Mart. I used my big rooster power supply that my friend gave me. The kit comes with some resistance wire from which your supposed the make a primitive current controller using a car battery or battery charger as a DC power source. I did buy a posh , very controllable DC power supply on flea-bay but it hasn't arrived after a few weeks, so I guess I'll be trying to get my money back on that one

Here's the set up, using my multi meter to monitor the voltage; there is an ammeter built into the power supply.

The kit takes up a fair bit of space, but is quite fun to use (no comments about me needing to get out more, thanks

)

You can't do many bits at a time, and given the time it takes, it's not cost effective, but there are three main advantages a) you can lose your own bits in your own workshop, you don't have to pay others to lose them in theirs D: b) If you need something in a hurry you can do it when you want it with no waiting nor driving c) when some one is admiring your bike, it's another bit you can claim you did yourself

Here's a shiny bright clear/blue passivated bit, without passivating it's a more yellow silver.

Here's a couple of bits I dipped in the olive drab passivate. At first they looked really crap, but then darkened down leaving a pleasing finish

I have found the fumes coming for my mini striping bath are too much for my asthmatic lungs to deal with so I have installed a fan in my workshop wall.

Now I can strip with impunity

I've also got one for the welding bench window, should be picking up the new pane of glass with the 'ole in it today

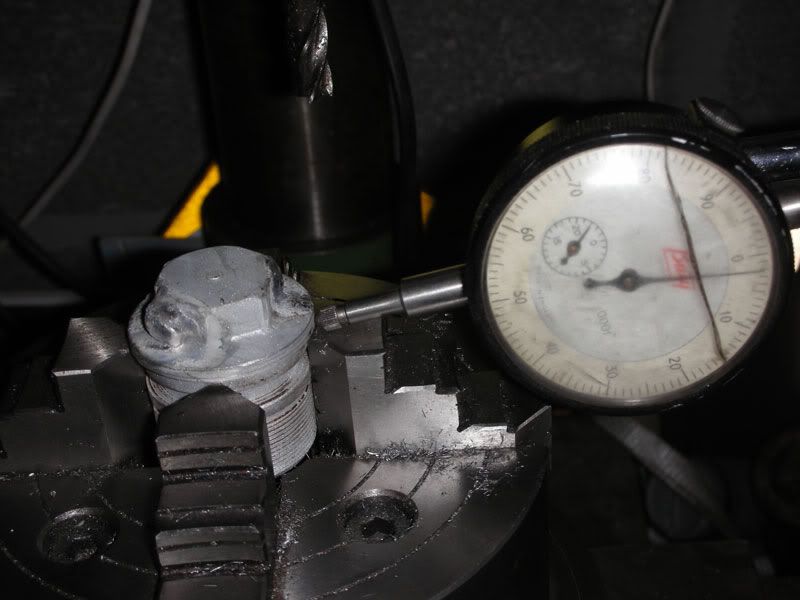

The head on this bike has been a bloody nightmare, as those of you following the whole thread will have noted, but the latest issue was an interesting one and should be noted by all playing with these heads.

The observant amongst you will notice that only half the cam cap bolts are installed. That it is because all the bolts I have had with this bike are 45mm. These are OK for the bolts with the dowels, but are too long for the other holes. I picked this up having had soooo much grief from these components. I noticed that in the parts book they should be 43mm. The plain portion of the 45mm bolts goes further than the cap itself. This might explain why the threads had all been chewed up and badly helicoiled, by some muppet who just increased the pressure when they wouldn't do up! The correct bolts are available by special order and the part number is 92002-1881 . They're not especially cheap, and despite having a pretty impressive bolt collection I couldn't find any. Yes, I could have cut the threads a bit further and nipped 2mm off the end, but they are rolled threads and I don't want to compromise the safety of the engine for the sake of a few quid

I dropped a bollock with my wheels - I masked up the centres, for some reason not thinking that they could be seen

Not sure what I'm going to do about that one yet.

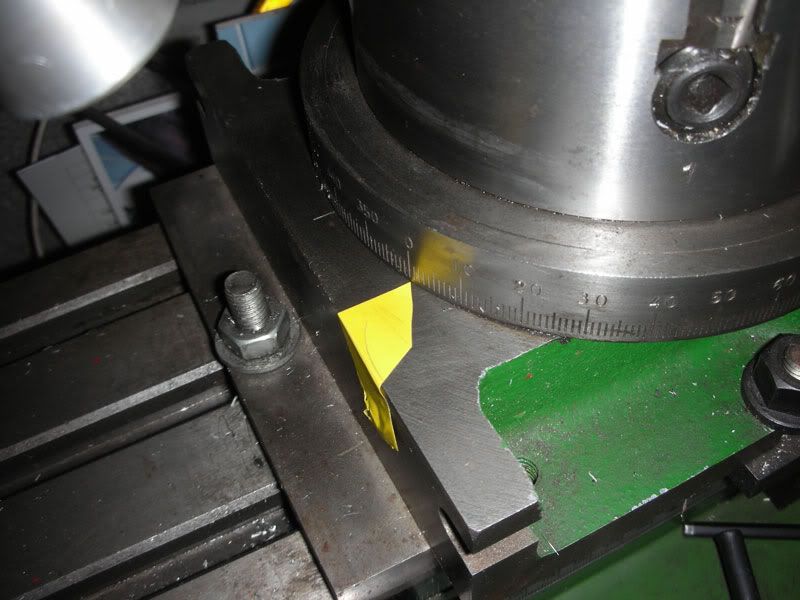

but wouldn't it have been quicker to buy a new fork top

but wouldn't it have been quicker to buy a new fork top