Hello Guest User,

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

new member with Z900 project

Moderators: KeithZ1R, chrisu, paul doran, Taffus

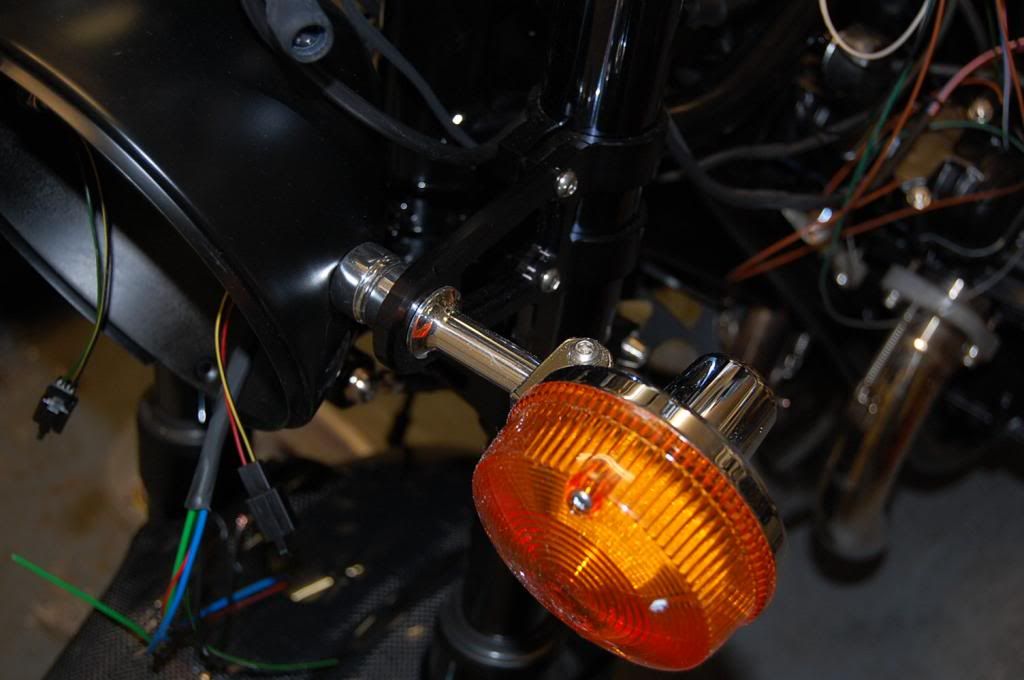

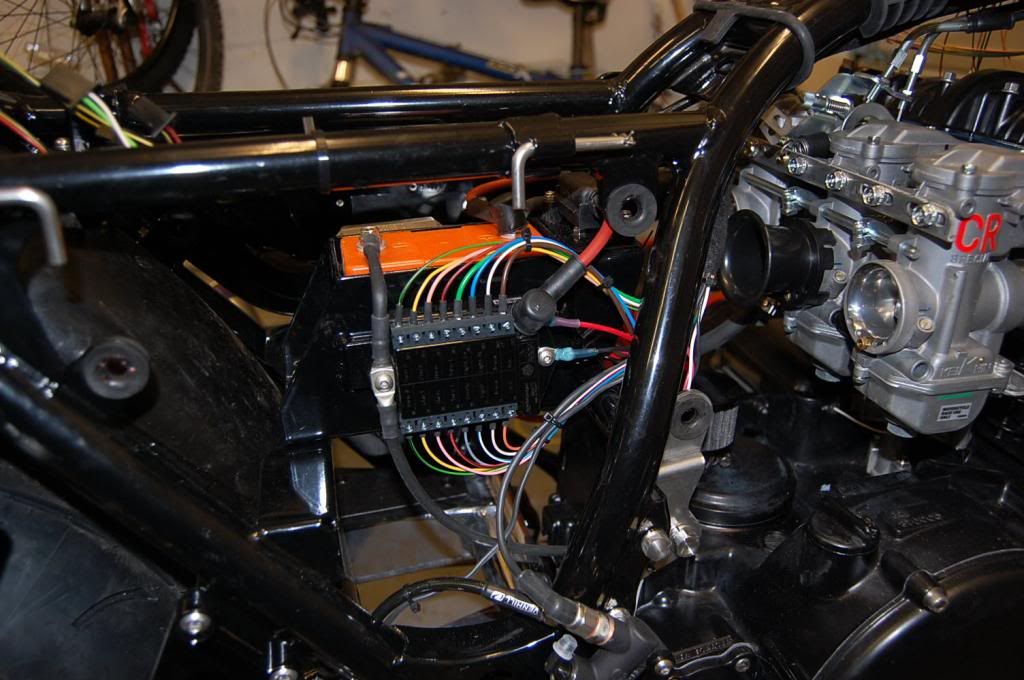

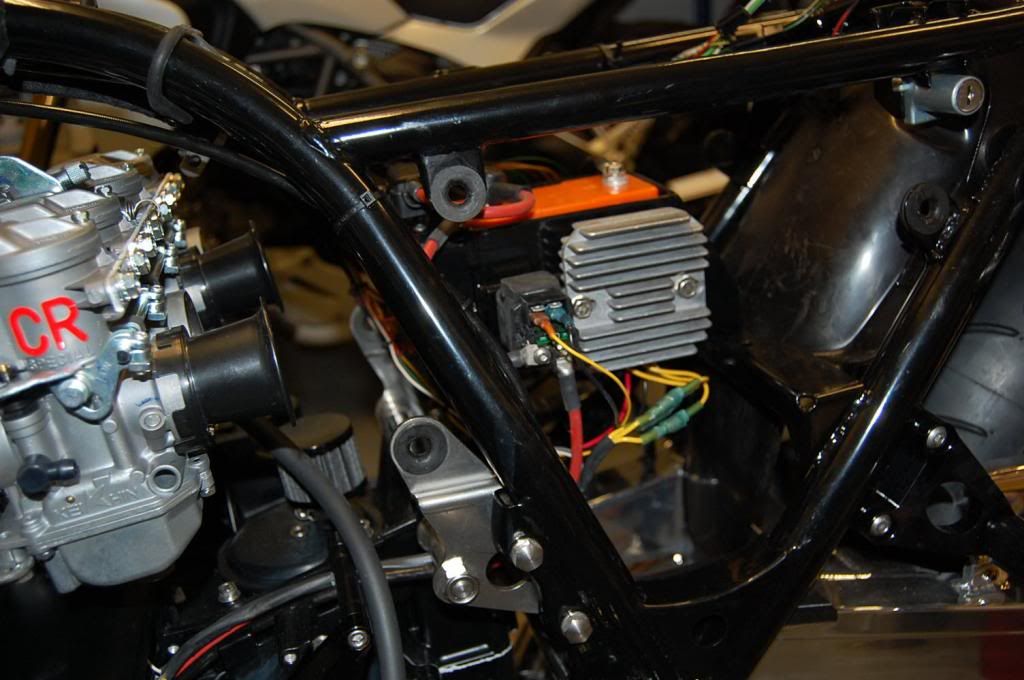

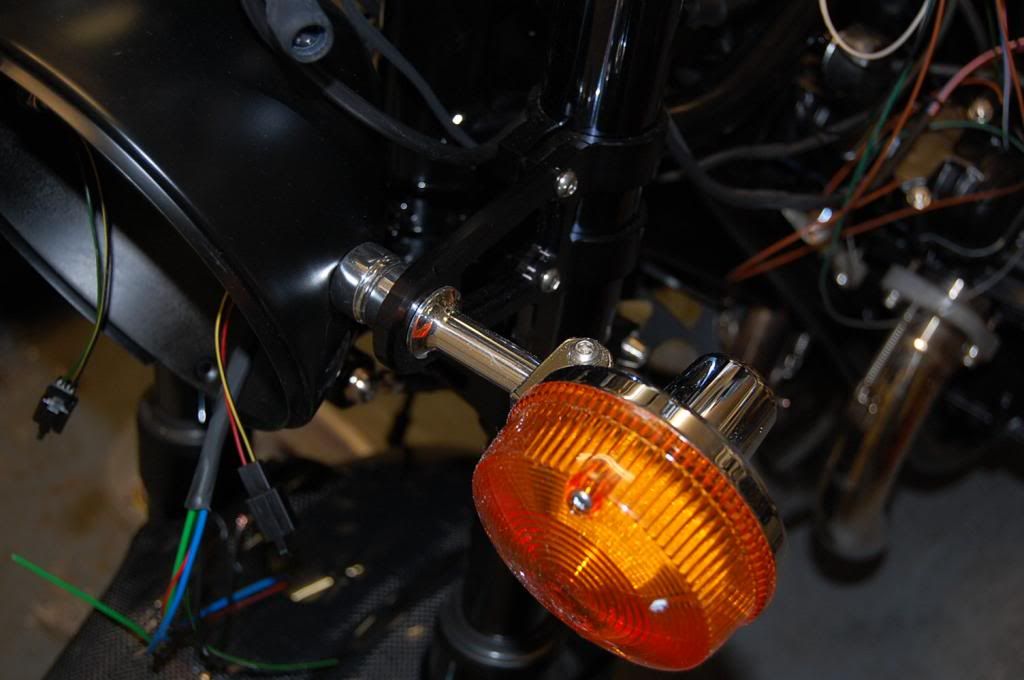

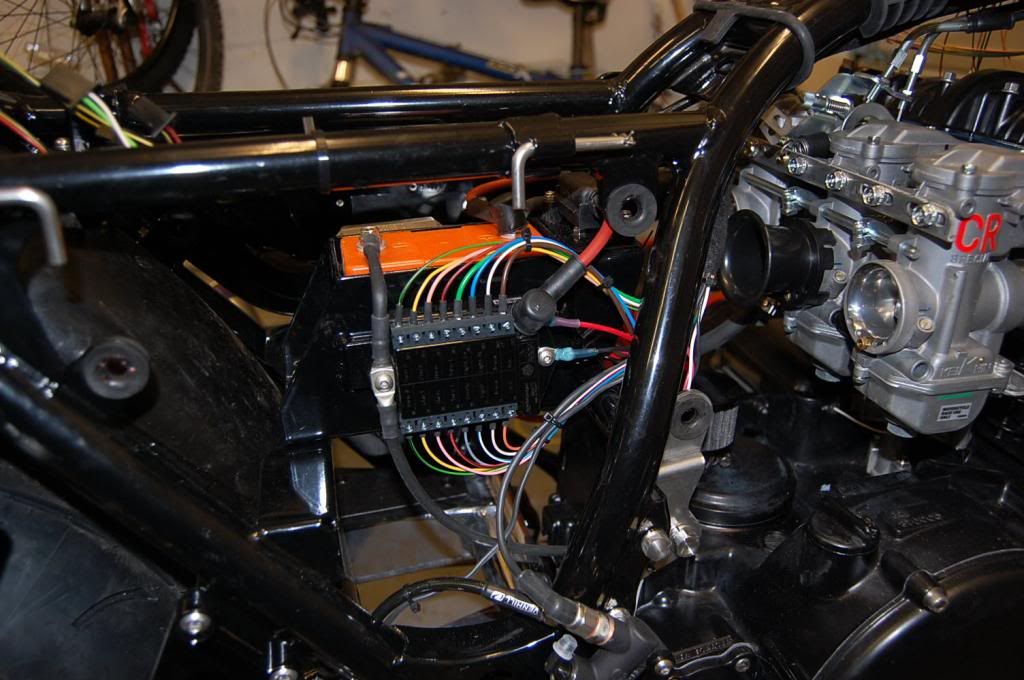

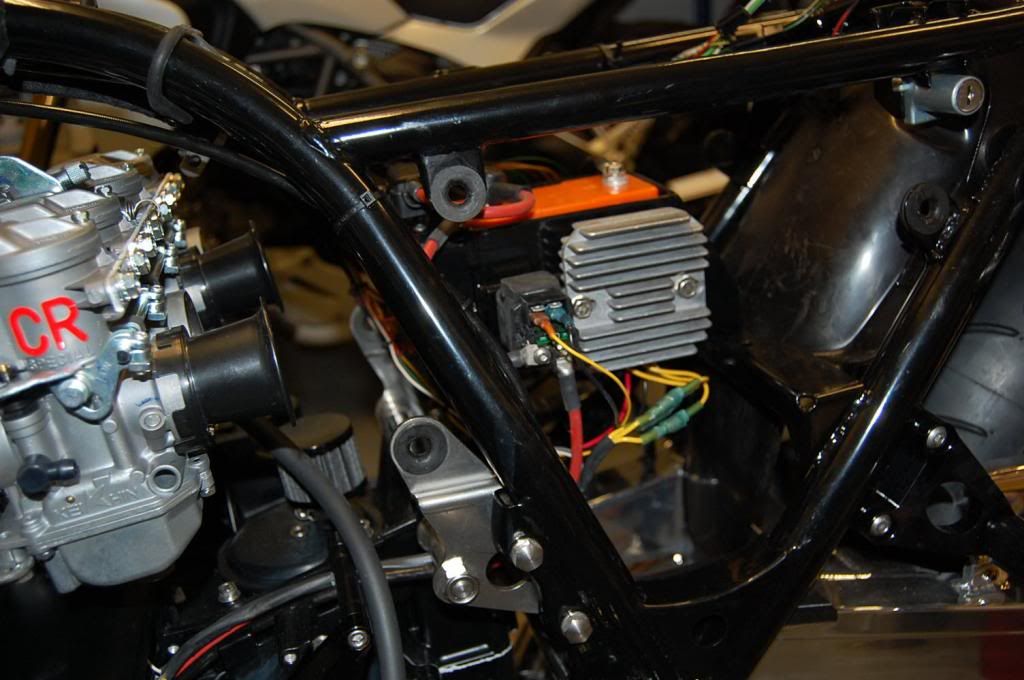

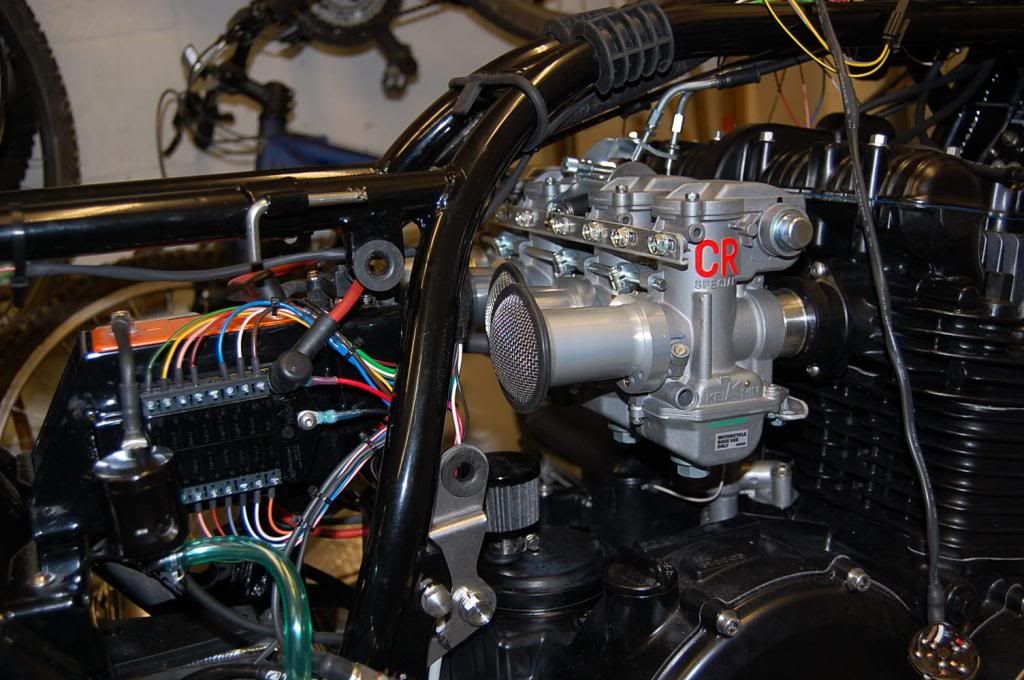

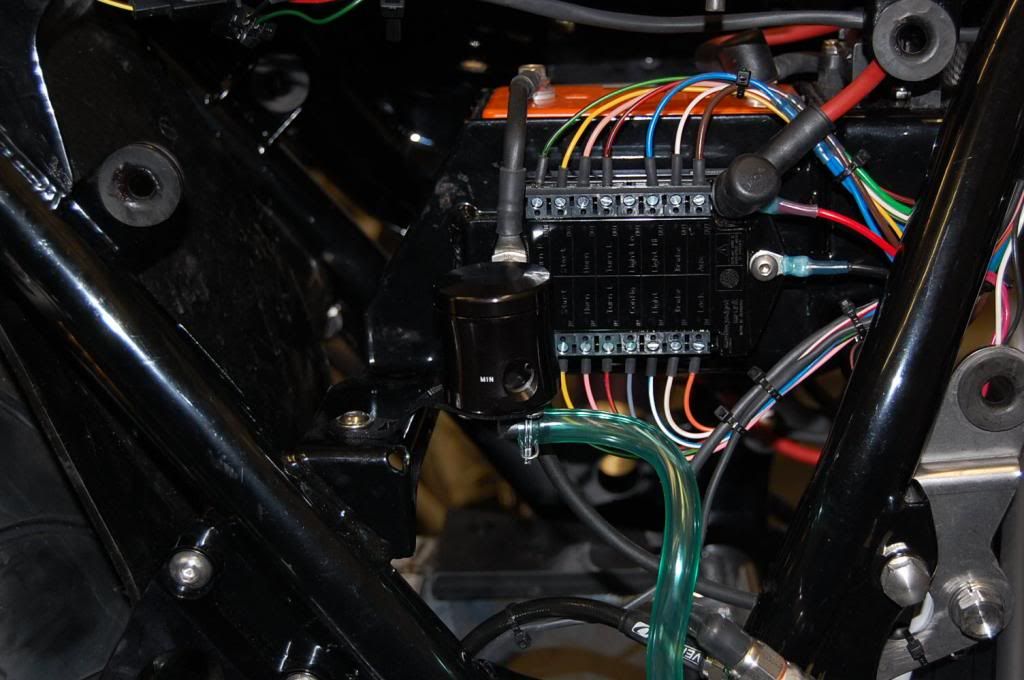

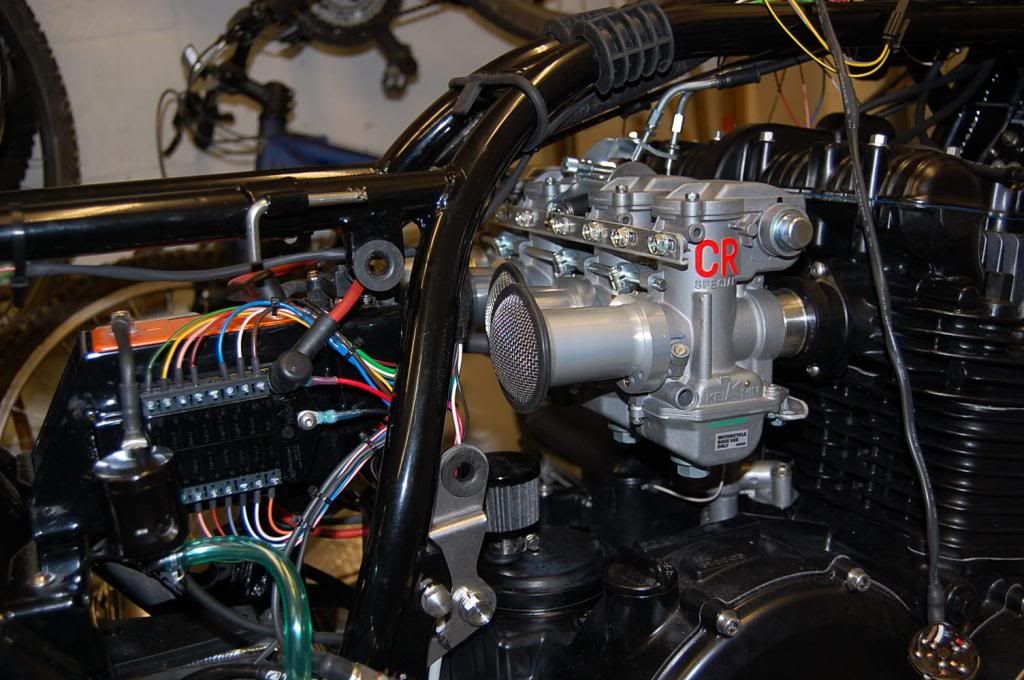

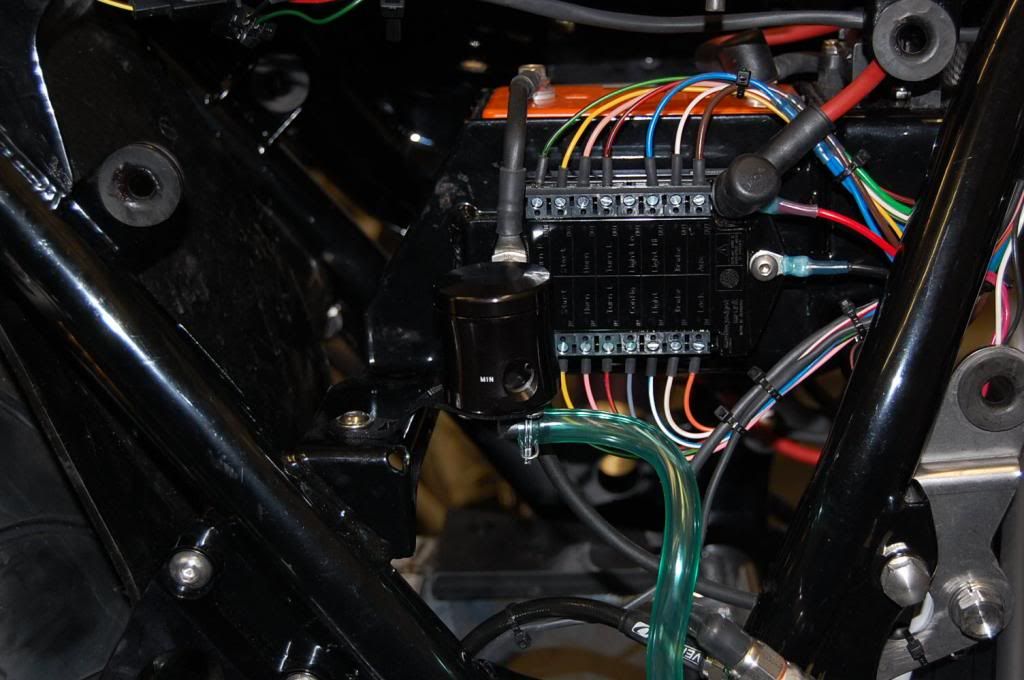

The wiring has been taking me longer than I expected. I am wiring it from scratch with all new modern components but it's 95% done now. Still left: speedo and tacho connections, LH switchgear and that's it. I've also fitted the headlight and indicators. I wasn't happy with the std stalks so I designed simple ones in polished alloy which serve the dual purpose at the front of securing the headlight shell.

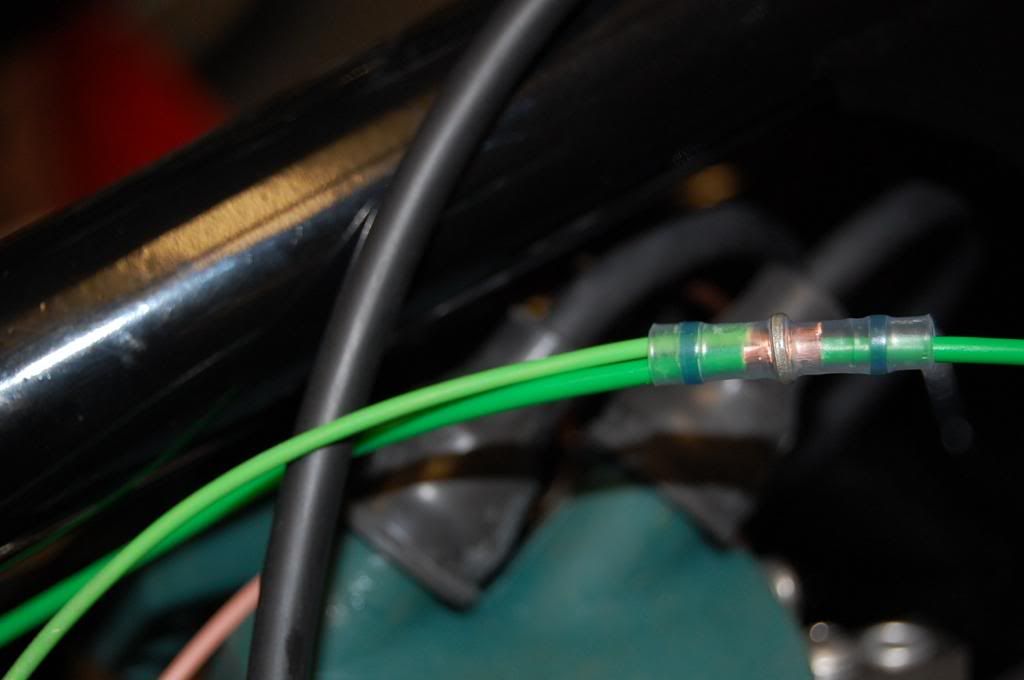

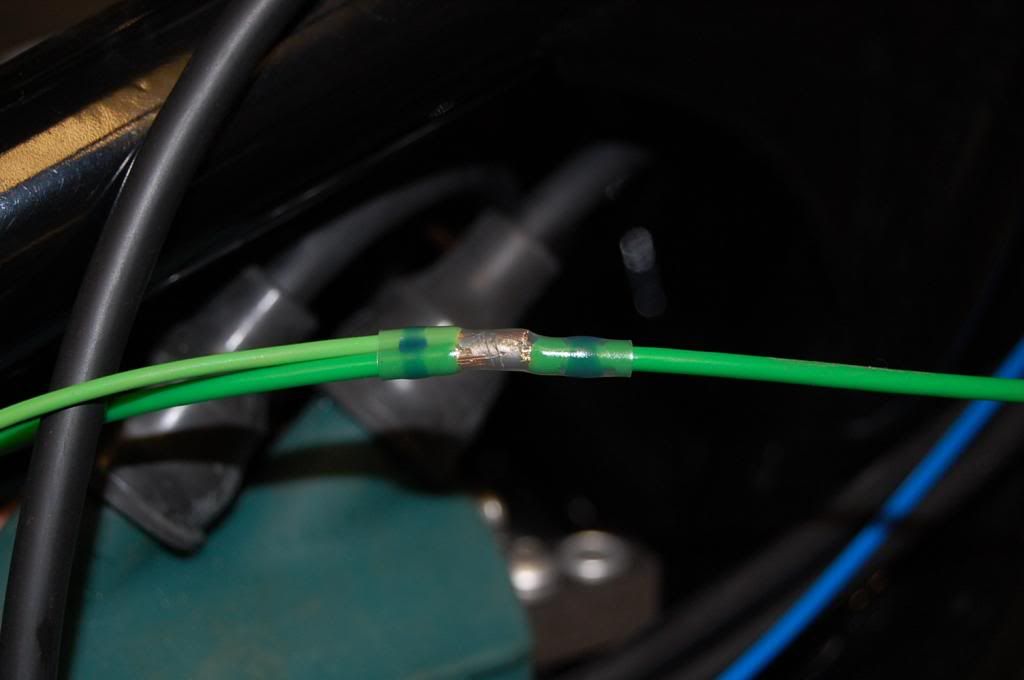

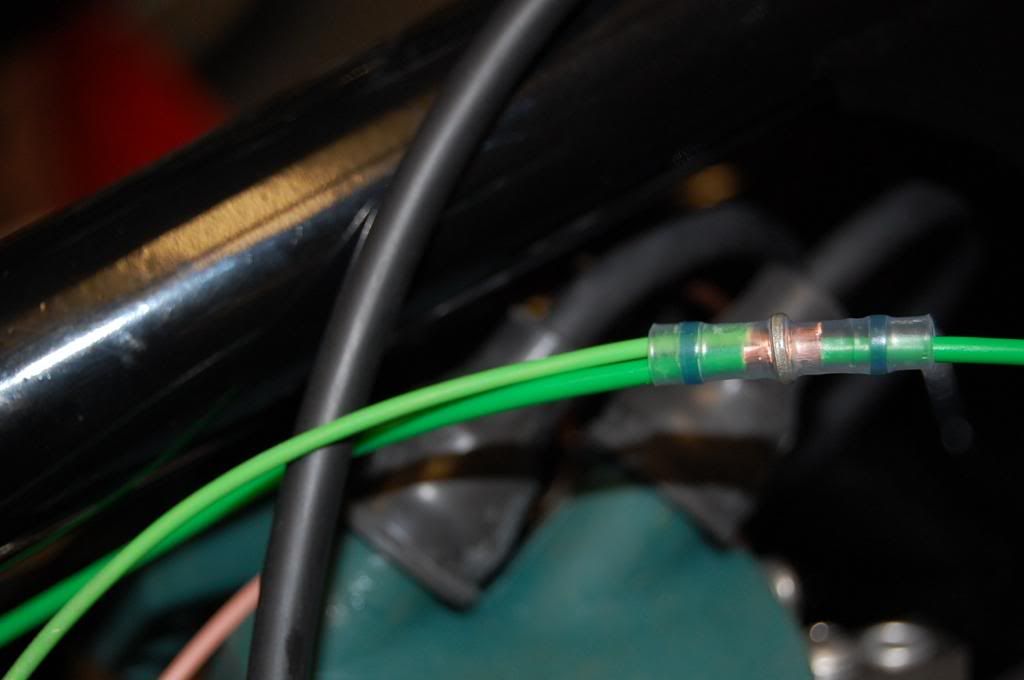

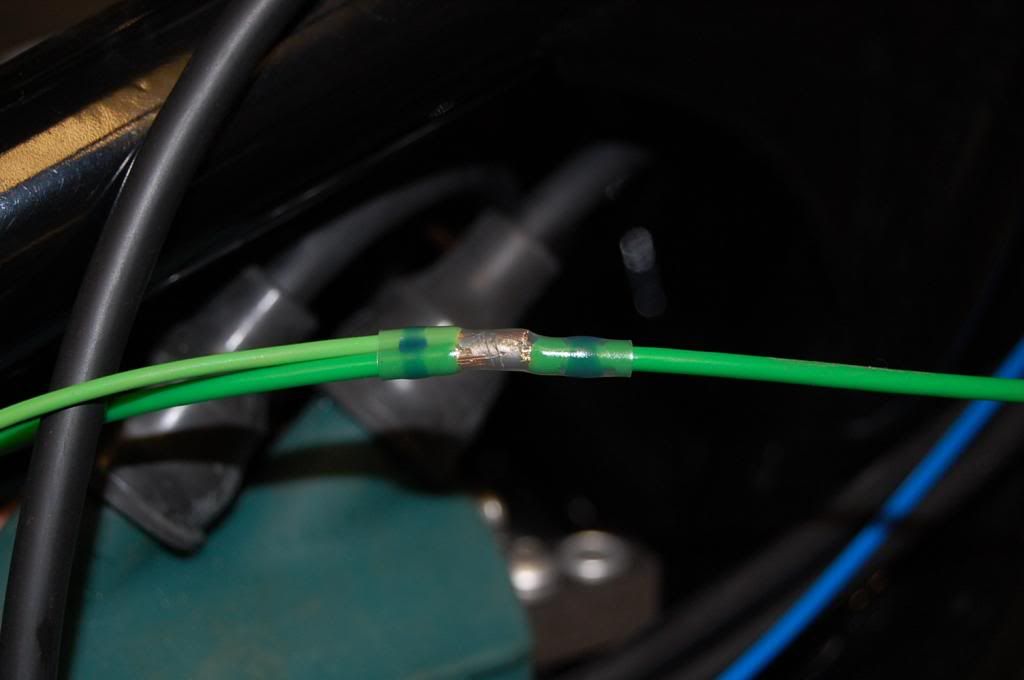

The wiring looks quite neat I think. The only messy bit will be under the tank where the connectors and splices go. I've been using solder sleeve splices which are an easy way of getting a high quality solder joint with strain relief and sealing all in one go. They're a bit fiddly but require minimal skill, just a hot air gun and a steady hand. I've attached a before and after pic so you can see how they work.

The headlight is an all-LED one from the US but it sits a bit proud of the shell at the front. I haven't decided whether this is going to look OK or not. The only way to fix this would be to get a custom bezel made which would be possible but actually quite tricky. I want the bike to have all LEDs, no bulbs.

I've already had the engine running without problems but the real test will be trying to ride it! Also still to do: hydraulics, tail tidy and various small jobs but it's getting close. I do plan to be at the Ace on 28th April, as does Lester Harris if he's not at a race meeting.

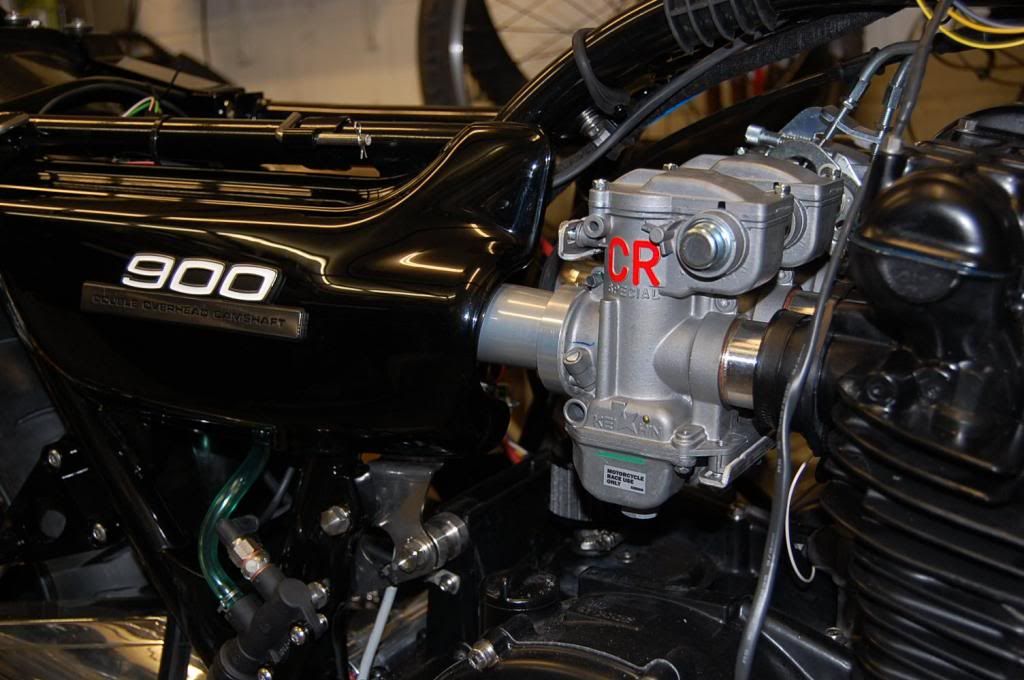

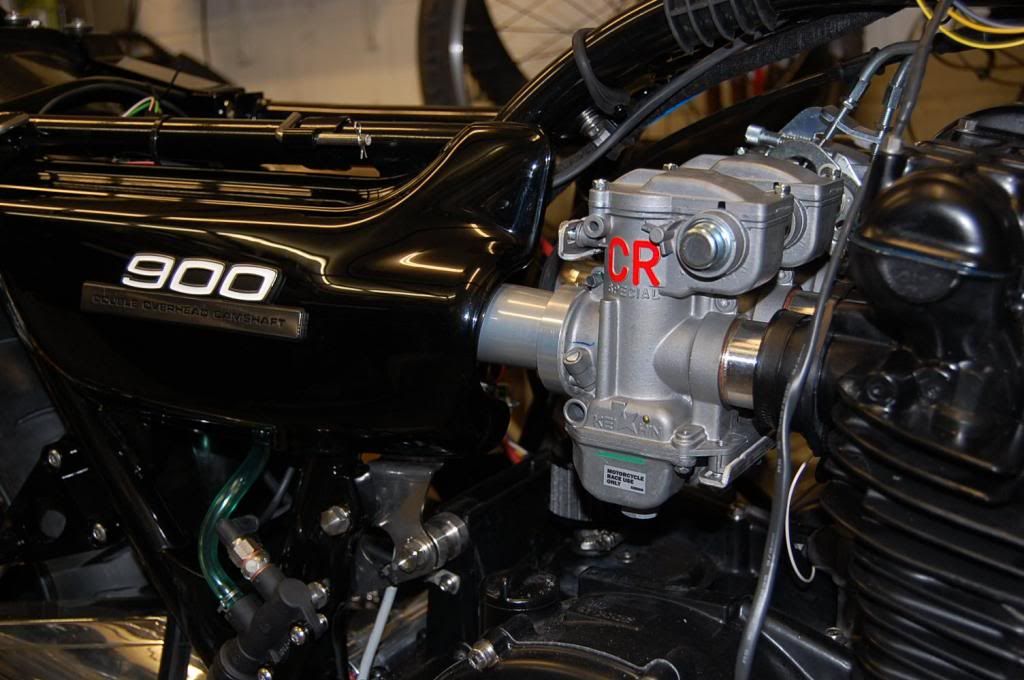

The oil cooler arrived from the US only 3 months after I ordered it. I have to remove the carbs to fit it so it's going to have to wait for now. I've found a solution for the air filters which doesn't mean cutting Si's beautifully painted side panels. I'll post a pic when the bits arrive from Japan.

The wiring looks quite neat I think. The only messy bit will be under the tank where the connectors and splices go. I've been using solder sleeve splices which are an easy way of getting a high quality solder joint with strain relief and sealing all in one go. They're a bit fiddly but require minimal skill, just a hot air gun and a steady hand. I've attached a before and after pic so you can see how they work.

The headlight is an all-LED one from the US but it sits a bit proud of the shell at the front. I haven't decided whether this is going to look OK or not. The only way to fix this would be to get a custom bezel made which would be possible but actually quite tricky. I want the bike to have all LEDs, no bulbs.

I've already had the engine running without problems but the real test will be trying to ride it! Also still to do: hydraulics, tail tidy and various small jobs but it's getting close. I do plan to be at the Ace on 28th April, as does Lester Harris if he's not at a race meeting.

The oil cooler arrived from the US only 3 months after I ordered it. I have to remove the carbs to fit it so it's going to have to wait for now. I've found a solution for the air filters which doesn't mean cutting Si's beautifully painted side panels. I'll post a pic when the bits arrive from Japan.

-

martinz1000r

- Custard Cream

- Posts: 955

- Joined: 1st Jul 2007

- Location: Oxfordshire

Hi London, wondered what air filters you settled on? I have exactly the same issue as you and really dont want to run open bell mouths on a road bike. Also wondered where you got the splices from. They only seem to come up on US eBay and Vehicle Wiring Products dont list them.

Z1000R, Moto Martin, z900 A4 Crosby Replica, Harris Magnum 2, Suzuki GSXR 1100 Slabbie, Yamaha YZF750SP, SP1 Hoonda, Katana 1100, Bimota SB6R

PMC in Japan make billet bellmouths for small CRs and also sell filters that fit inside to provide protection. Probably not as good as a proper filter but much much better than nothing. I have ordered two short and two long on the basis that if the short doesn't fit the long should and vice versa. Apparently the combination of 2 long and 2 short is good for midrange and top end, which may even be true.

http://www.win-pmc.com/other/carburetor ... _ripea.htm

You can buy solder sleeves from RS components in the UK. They work best with a heat gun which has a reflector, which helps to heat the splice all round.

http://uk.rs-online.com/web/p/solder-sl ... s/5425583/

http://www.win-pmc.com/other/carburetor ... _ripea.htm

You can buy solder sleeves from RS components in the UK. They work best with a heat gun which has a reflector, which helps to heat the splice all round.

http://uk.rs-online.com/web/p/solder-sl ... s/5425583/

LondonZ1 wrote:Martin, you can also buy just the PMC/CR filters separately and use them with a standard plastic CR bellmouth. The filters are only about a fiver each. I have a parcel being dispatched from Japan shortly, I can ask Drew to supply 4 more filters if you want. PM me if you are interested.

Filters on cr's.......nnnnnnnnnnoooooooooooooooooo!!!!!!!!!!!!!!

-

Royalratch

- 100Club

- Posts: 366

- Joined: 3rd Jul 2009

- Location: London

Looks awesome dude. Same approach with my project - modern and as etch / reliable as possible but classic Z-lines and motor.

I'm not going with any clocks and have just 2 visible buttons (Motogadget also) on the left bar.

I think a black exhaust would make this look perfect - a shiny ceramic coated finish?

I'm not going with any clocks and have just 2 visible buttons (Motogadget also) on the left bar.

I think a black exhaust would make this look perfect - a shiny ceramic coated finish?

-

Anuar Kamaruddin

- Regular Poster

- Posts: 64

- Joined: 8th Aug 2011

- Location: Kuala Lumpur,Malaysia

I'm in awe of your wiring, I can't wait to sort the wiring out on my project too

when I get to that stage, as I'm a perfectionist with that sort of thing as well.

when I get to that stage, as I'm a perfectionist with that sort of thing as well.

Last edited by Jay1969 on Wed May 22, 2013 10:23 pm, edited 1 time in total.

Haven't had much time to spend on the bike recently so progress has been slow. I have managed to make a tail tidy and fit the rear light. It's a standard Z900 lens but mounted to a rear plate made out of acetal and fitted with an LED insert. I've also fitted some billet bellmouths with filters from Japan which fit neatly inside the Z1 side panels. You can't see the filters when the side panels are fitted.

I spent ages looking for a small and good quality rear brake reservoir and eventually bought one from ABM in Germany. In fact I liked it so much I fitted two more to the handlebars. The hydraulics are all ready to go now, just need to to fill with fluid. I'm a bit concerned that the clutch push rod might need modifying but I guess that's not a big job.

The electrics are close I but have been having problems with the design. I discovered late in the day that the dipped beam feed from m-unit turns off when you select main beam. As I had wired the tail light into the dipped beam circuit, this meant a small redesign. The front tank mounts are also slightly too narrow for the tank. I have no idea why but the simple solution is to use some stainless tube to make the mounts protrude about 5mm further. Why is it always the case that the small things at the end take much longer than expected?

Left to do: bleed brakes and clutch, wire up instruments when the dash is back from polishing by Mikey, tank mounts and drill holes in the bars for the switchgear lugs. Then fit a chain and get an MOT. It's getting close...

I spent ages looking for a small and good quality rear brake reservoir and eventually bought one from ABM in Germany. In fact I liked it so much I fitted two more to the handlebars. The hydraulics are all ready to go now, just need to to fill with fluid. I'm a bit concerned that the clutch push rod might need modifying but I guess that's not a big job.

The electrics are close I but have been having problems with the design. I discovered late in the day that the dipped beam feed from m-unit turns off when you select main beam. As I had wired the tail light into the dipped beam circuit, this meant a small redesign. The front tank mounts are also slightly too narrow for the tank. I have no idea why but the simple solution is to use some stainless tube to make the mounts protrude about 5mm further. Why is it always the case that the small things at the end take much longer than expected?

Left to do: bleed brakes and clutch, wire up instruments when the dash is back from polishing by Mikey, tank mounts and drill holes in the bars for the switchgear lugs. Then fit a chain and get an MOT. It's getting close...

-

Darren Williams

- 100Club

- Posts: 116

- Joined: 23rd Sep 2008

- Location: BANGOR

- Ginger Bear

- Hardcore

- Posts: 6850

- Joined: 16th Dec 2008

- Location: In the Dark.

- Contact:

Here you go Ginger Bear http://www.ab-m.de/

I have finally finished the wiring, and it all works. I wired up the speedo and tacho but both need to be programmed to tell them the rear wheel size and engine configuration. The bike starts on the button but I need to locate someone not too far from SW London who can set up the timing and carbs; suggestions welcome. I haven't put fluid in the hydraulics yet and I need to make a number plate hanger and drill holes in the bars for the switchgear lugs. There are also lots of very minor things to tidy up but it's almost done. I'll get the local bike shop to fit a chain when I get the MOT done; I don't have a chain splitter. The wiring under the gauges is not quite as neat as I would like but the harness that comes with the stack tacho was designed for functionality not style. I was going to build my own until I discovered that the stack harness uses screened cables and incorporates 2 resistors. I gave up at that stage....

Mikey did a lovely job of polishing the dash and anodising the instrument cans black. I wanted the instrument to look traditional in style but with modern gauges and without looking home-made.

The oil cooler will have to go on later, I want to get it on the road first. I will book the MOT for early April and if that goes OK then I should be on the Ace Cafe on 28th.

Mikey did a lovely job of polishing the dash and anodising the instrument cans black. I wanted the instrument to look traditional in style but with modern gauges and without looking home-made.

The oil cooler will have to go on later, I want to get it on the road first. I will book the MOT for early April and if that goes OK then I should be on the Ace Cafe on 28th.

Who is online

Users browsing this forum: No registered users and 12 guests