j.wilson wrote:yea, but disposing of the body is ALWAYS the biggest problem.

Sausages

Moderators: KeithZ1R, chrisu, paul doran, Taffus

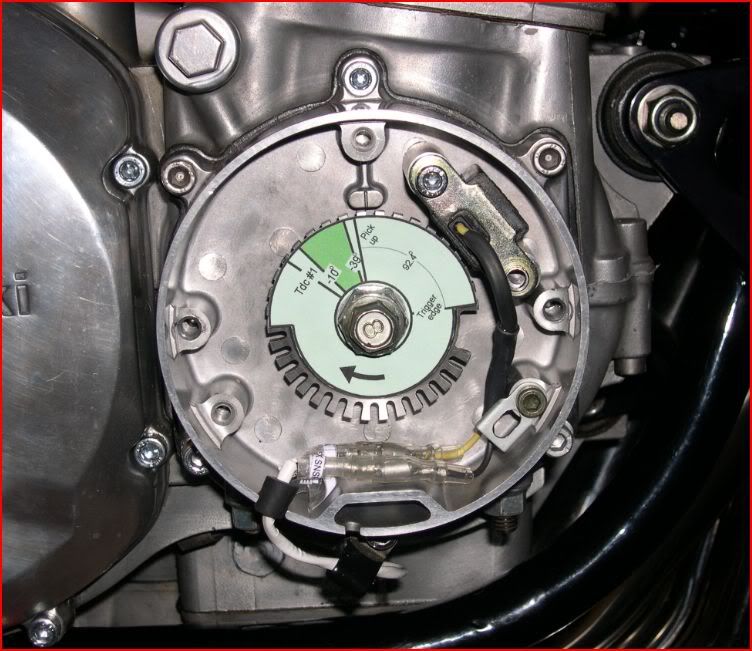

j.wilson wrote: The only problem I had was that the indicator idiot light needed a bulb fitted in the circuit to give a load to make the flash rate right.

Users browsing this forum: No registered users and 6 guests