JMC swing arm.

Posted: Sat Apr 18, 2009 9:51 pm

Possibly the worst service from any company I have experienced in the last few years.

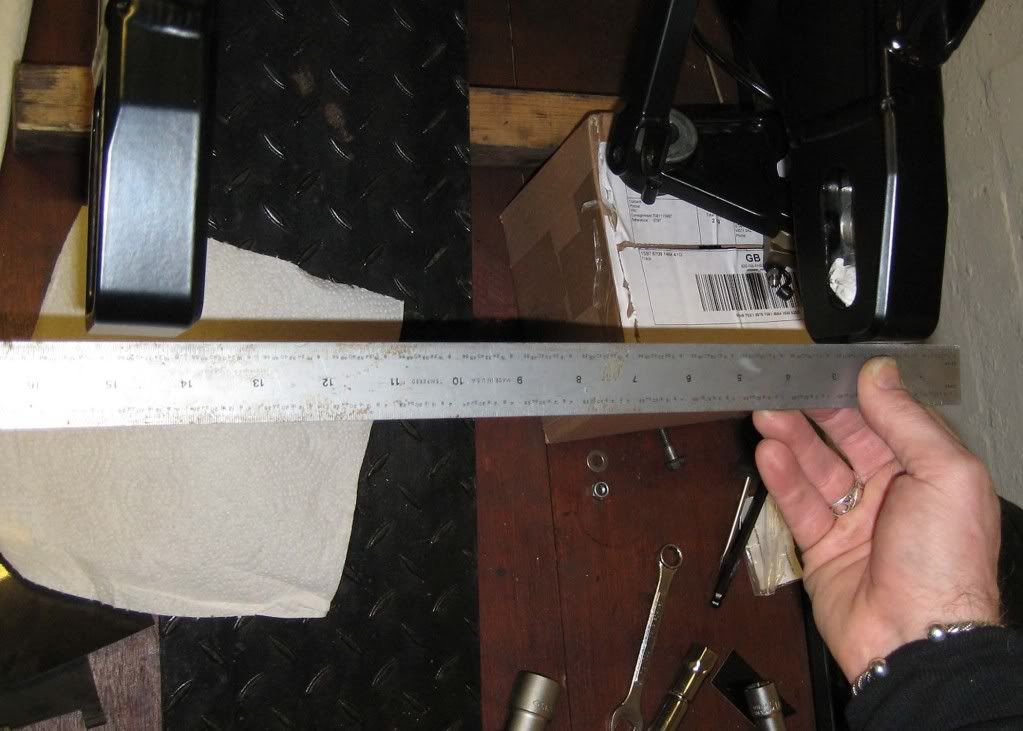

Having waited about 7 months for my JMC swing arm, and been given excuse after excuse, tonight I have tried to fit it.

THe standard swing arm fitted fine, and the Dresda one I fitted a couple of years ago fitted fine. So was not expecting any problems.

Several hours later I have given up in disgust for the time being.

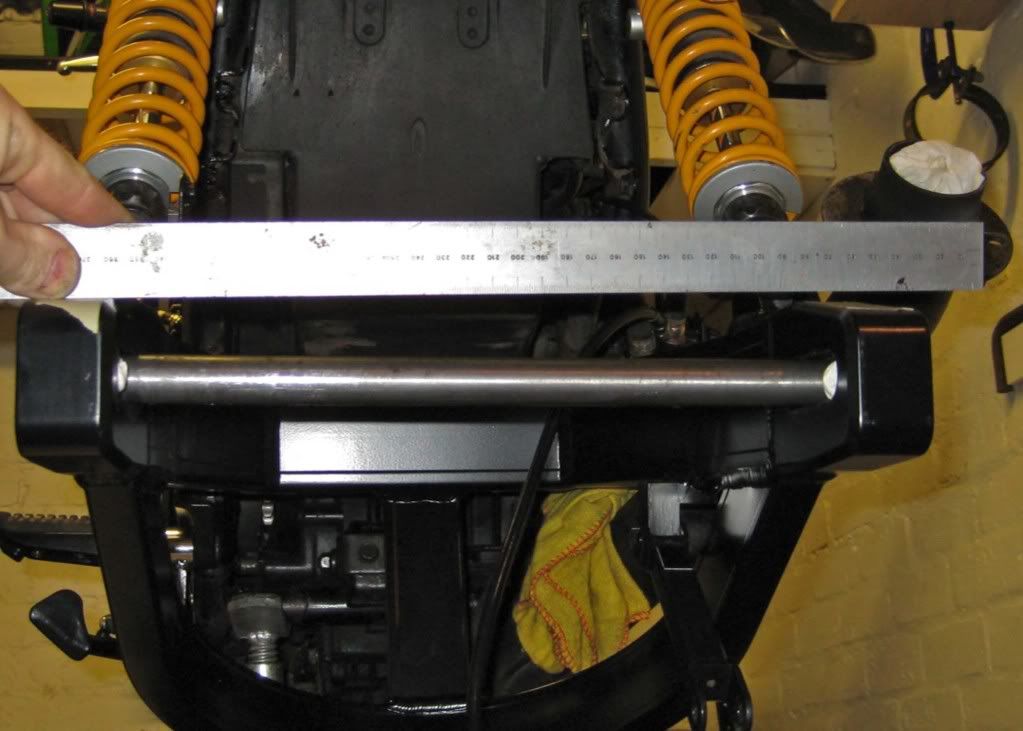

First problem it did not fit between the frame tubes, just too tight after a lot of mucking about filing the frame and the spacers in the swing arm finally got it in and went to get a Becks to celebrate. Swung it up to bolt the shocks on to find it hits the lugs which the exhausts would bolt too I presume if I had a 4 into 4 on the frame tubes that support the pillion pegs.

I have been filing away at them for a while with a knackered old file but will have to get to B and Q in the morning to buy an angle grinder.

Well pissed off, and its made of such a soft alloy that its now scratched.

In addition I am not impressed with the fact the shocks bolt on to a plate on one side rather than having a plate on either side, nor am I impressed with the back axle arrangement which has a nyloc nut each side meaning to adjust the chain etc. I will need 2- 24mm sockets, and any way are you not supposed to not reuse nyloc nuts?

They arent cheap either and I wish I had saved my money

Having waited about 7 months for my JMC swing arm, and been given excuse after excuse, tonight I have tried to fit it.

THe standard swing arm fitted fine, and the Dresda one I fitted a couple of years ago fitted fine. So was not expecting any problems.

Several hours later I have given up in disgust for the time being.

First problem it did not fit between the frame tubes, just too tight after a lot of mucking about filing the frame and the spacers in the swing arm finally got it in and went to get a Becks to celebrate. Swung it up to bolt the shocks on to find it hits the lugs which the exhausts would bolt too I presume if I had a 4 into 4 on the frame tubes that support the pillion pegs.

I have been filing away at them for a while with a knackered old file but will have to get to B and Q in the morning to buy an angle grinder.

Well pissed off, and its made of such a soft alloy that its now scratched.

In addition I am not impressed with the fact the shocks bolt on to a plate on one side rather than having a plate on either side, nor am I impressed with the back axle arrangement which has a nyloc nut each side meaning to adjust the chain etc. I will need 2- 24mm sockets, and any way are you not supposed to not reuse nyloc nuts?

They arent cheap either and I wish I had saved my money