Exhaust Baffle Material

Posted: Thu Feb 26, 2009 6:02 am

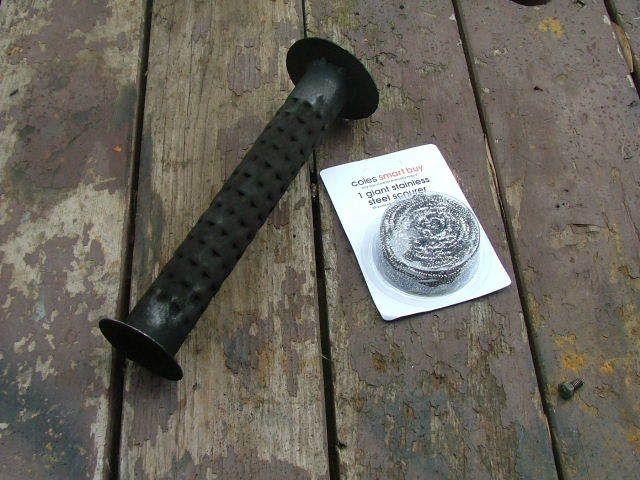

Talking about "four into ones" in particular and spurred on by thread "Exhausting Business" in Discussions, where it is generally advocated that oil be poured/ sprayed into the baffle be prevent corrosion.

My question is: What is the best material to use to wrap around the baffle tube?

I had a problem with lack of performance with a particular muffler. Tried another and the difference was remarkable. Now looking at both mufflers, they are approx the same dimensions and the same physical shape, the only difference apparent, was one had the perforated baffle tube wrapped in insulating wool and wired on, the other was the same, however, it was matted with black soot and oil soaked. This later one (sooty & oil soaked) was the poor performer. Hence, it looked as the presence of oil over a period may effect performance.

These exhaust systems were not expensive high performers, they were just run of the mill .. Tranzac or Walker etc. Anyone with some good ideas as to what material to wire on around the baffle tube? It's a bit loud with-out any baffle material wrapped around the tube.

RegardZ.

My question is: What is the best material to use to wrap around the baffle tube?

I had a problem with lack of performance with a particular muffler. Tried another and the difference was remarkable. Now looking at both mufflers, they are approx the same dimensions and the same physical shape, the only difference apparent, was one had the perforated baffle tube wrapped in insulating wool and wired on, the other was the same, however, it was matted with black soot and oil soaked. This later one (sooty & oil soaked) was the poor performer. Hence, it looked as the presence of oil over a period may effect performance.

These exhaust systems were not expensive high performers, they were just run of the mill .. Tranzac or Walker etc. Anyone with some good ideas as to what material to wire on around the baffle tube? It's a bit loud with-out any baffle material wrapped around the tube.

RegardZ.