Valve Clearance, Check Please!

Posted: Mon Mar 30, 2015 2:21 am

Hi Guy’s

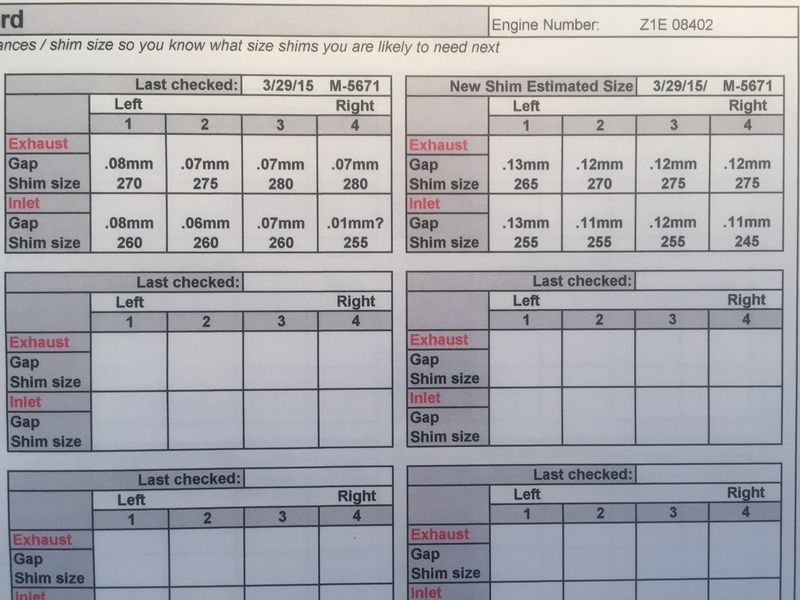

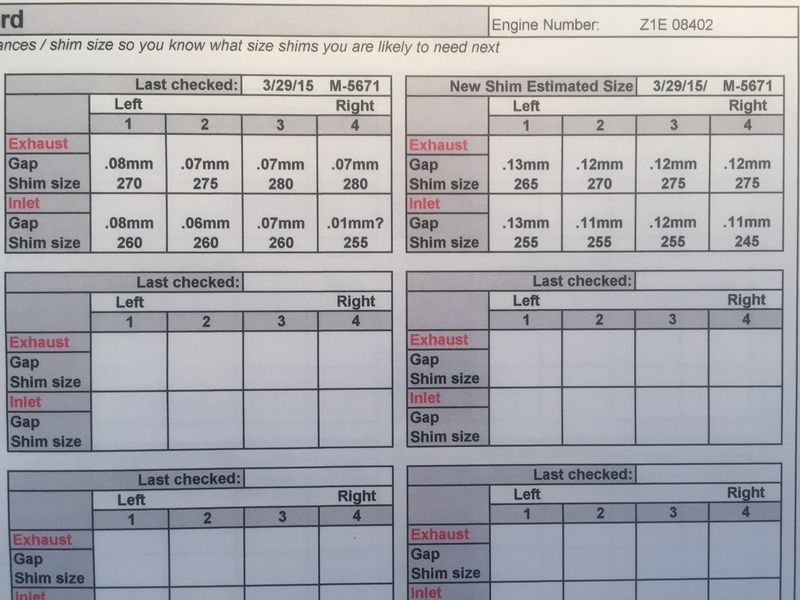

1973 Z1900 with 5671 miles

Please check me on this as I am a first timer on adjusting the valve shims. The column on the left “ Last Checked “ is the current size shim and the clearance on each valve as it sits today and the column on the right “ New Shim Estimated Size “ is what I calculate to be the new shim size and clearance to get all valves between .10mm - .15mm of clearance. Intake on #4, I cannot get a .04mm feeler gauge in there as it is too tight, I tried a piece of .02mm aluminum foil but it was too tight. I can rotate the bucket so I know there is clearance I am guessing on the .01mm. I used the Motion Pro shim tool which was less than fun due to its small size and with a little oil on your hands just makes it a real joy to deal with. The Kawasaki tool looks a lot easier to use so I my try to find one before I change the shims out. Thanks

1973 Z1900 with 5671 miles

Please check me on this as I am a first timer on adjusting the valve shims. The column on the left “ Last Checked “ is the current size shim and the clearance on each valve as it sits today and the column on the right “ New Shim Estimated Size “ is what I calculate to be the new shim size and clearance to get all valves between .10mm - .15mm of clearance. Intake on #4, I cannot get a .04mm feeler gauge in there as it is too tight, I tried a piece of .02mm aluminum foil but it was too tight. I can rotate the bucket so I know there is clearance I am guessing on the .01mm. I used the Motion Pro shim tool which was less than fun due to its small size and with a little oil on your hands just makes it a real joy to deal with. The Kawasaki tool looks a lot easier to use so I my try to find one before I change the shims out. Thanks