Gearbox trouble

Posted: Sun Dec 30, 2007 11:40 pm

I've just un-split the crankcases. After many happy (not) hours degeasin' I finally was ready to glue th ecrank cases back together, Rather than my old faithful (red hermetite) I followed advice from a pal and used Wellseal for a less obvious job. I had torqued down the mains and was just running around the 6mm bolts at 7ft/lb, when I had gried from one bolt. It was turning with too little resitance, but not little enough to be stripping. I had a nasty feeling that it was going to be a weakened bolt and sure enough ir went PING  The temptation to say ruck it and glue the sod in place was almost too much. But I did the right thing and undid everything and rand round cleaning the uber sticky Wellseal from all mating faces.

The temptation to say ruck it and glue the sod in place was almost too much. But I did the right thing and undid everything and rand round cleaning the uber sticky Wellseal from all mating faces.

Clearly I wasn't gonna find a new bolt that lenghth so I grabbed a bit o 1/4" 316 SS off the shelf and turned the threaded bit down to 6mm, having assertained that the casing holes could accept 1/4". I grabbed a 6mm nut and bored it 1/4" and then TIGGED it to the top of the bar and with a quick faceoff in the lathe I had a new bolt. There was a bit o clenchy sphincter as I torqued it down for the second time, but it was fine proving that the bolt must have been weak.

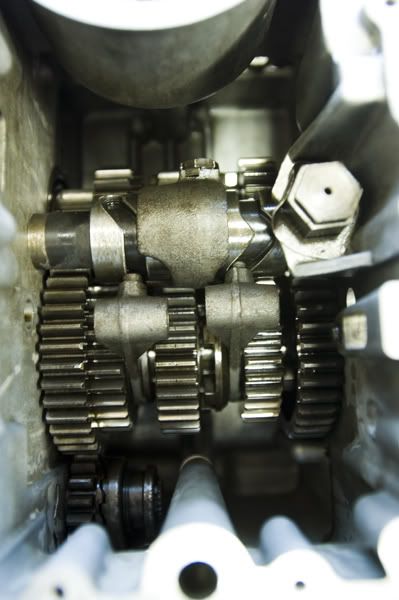

Can you imagine my joy when I found that the fourth gear on the output shaft wont come across enough to fit the selector fork when it is engaged in the profile I have absolutely no idea why the bast#*& wont come across. It doesn't go tight but comes to a positive mechanical stop.

I have absolutely no idea why the bast#*& wont come across. It doesn't go tight but comes to a positive mechanical stop.  I just can't work it out but I really, really don't want to split the crankcases again if at allow possible. I never removed the selection drum from the casing and as I only split the crank cases because shit fell down when the barrels where removed I didn't take the clutch off either, and I didn't take either shafts apart either. Something is clearly wrong but I'm buggered if I can work out what

I just can't work it out but I really, really don't want to split the crankcases again if at allow possible. I never removed the selection drum from the casing and as I only split the crank cases because shit fell down when the barrels where removed I didn't take the clutch off either, and I didn't take either shafts apart either. Something is clearly wrong but I'm buggered if I can work out what

Any suggestions would be greatly appreciated.

Thanks

Clearly I wasn't gonna find a new bolt that lenghth so I grabbed a bit o 1/4" 316 SS off the shelf and turned the threaded bit down to 6mm, having assertained that the casing holes could accept 1/4". I grabbed a 6mm nut and bored it 1/4" and then TIGGED it to the top of the bar and with a quick faceoff in the lathe I had a new bolt. There was a bit o clenchy sphincter as I torqued it down for the second time, but it was fine proving that the bolt must have been weak.

Can you imagine my joy when I found that the fourth gear on the output shaft wont come across enough to fit the selector fork when it is engaged in the profile

I have absolutely no idea why the bast#*& wont come across. It doesn't go tight but comes to a positive mechanical stop.

I have absolutely no idea why the bast#*& wont come across. It doesn't go tight but comes to a positive mechanical stop. Any suggestions would be greatly appreciated.

Thanks