Page 1 of 2

Early Z1 carb repair. Suggestions wanted.

Posted: Mon Mar 17, 2014 11:13 am

Author: ruffle

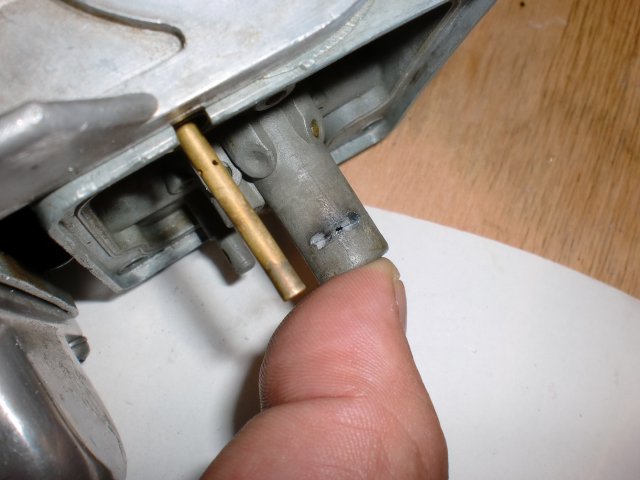

At the tail end of last year my '72 suddenly started running horribly and I found that the 'boss' in the carb bowl that the emulsion tube screws into had broken and fallen off on No1 pot (someone in the last 42 years had obviously screwed it in too tight at some time and cracked it; not me I hasten to add!

).

I've tried getting another carb body but all the ones I've found are the '73/Z1A type with the larger ribs. I'd really like to repair this carb body so I'm looking for suggestions.

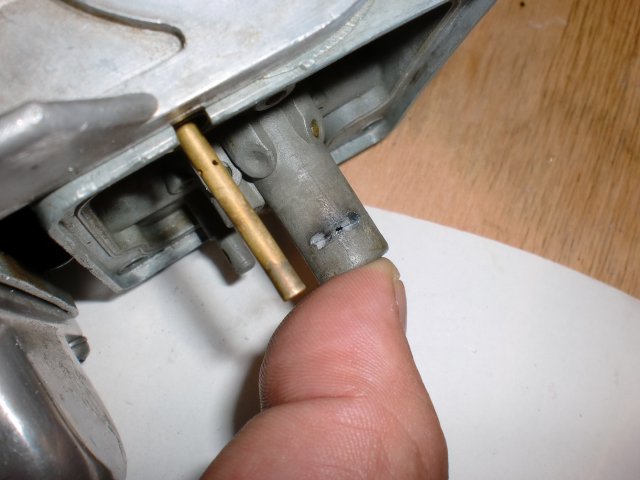

Here's the broken bit:

Ideas I've had so far (comment and suggestions very very welcome):

A) Epoxy (JB Weld) glue it back together (the break is such that the parts locate back together nicely) and reinforce around the outside with more epoxy glue/putty. I've googled and some say JBWeld is fine immersed in petrol and other say it'll dissolve in days.

B) Glue it (superglue or somesuch just to hold it temporarily) and heat shrink on a thin aluminium sleeve to hold and reinforce it.

C) Get it micro/laser welded back on (I've found a chap in the USA who's been repairing H*dna carbs in this way

http://forums.sohc4.net/index.php?topic=118804.0 and there are firms advertising laser welding for micro welds a bit closer to home. Anyone got a recommendation?).

D) Errr..... over to you guys. Ideas please.

Posted: Mon Mar 17, 2014 12:10 pm

Author: z1bman

Posted: Mon Mar 17, 2014 12:39 pm

Author: Mowjoe

Devcon epoxy may do it if it's ok with fuel. google it and look at specs. I've seen it used offshore for a range of industrial repairs.

Posted: Mon Mar 17, 2014 12:52 pm

Author: malmojoe

here's a spare body for $65 form o7/73 by the looks of it. I'm not sure but it should be the same as yours except the web (??) but you could just get a flat file on that, then a bit of wet+dry.

http://www.ebay.com/itm/Z1-Mikuni-28mm-Carb-BODY-1-For-1973-74-Kawasaki-Z1-KZ900-17mm-Bowl-Screws-/351013032897?hash=item51ba01d3c1&vxp=mtr

Posted: Mon Mar 17, 2014 1:10 pm

Author: ruffle

Thanks for the replies so far.

Lumiweld; I've used it before (very useful for building up broken choke mounts on triples) but I'd have to get the whole carb pretty hot and I'd be worried about heat distortion. AFAIUI, laser welding generates very localised heat.

Devcon possible. According to JBWeld, their marine epoxy is impervious to petrol once cured so that's a possibility.

Carb body on EBay; I've already got a couple like that and a full '73/Z1A set but I'd really like to keep the '72s if possible. As it's the #1 (left hand) carb any gross filing hackery on my part would be very visible!

Posted: Mon Mar 17, 2014 1:26 pm

Author: Mark Tiller

I would try the Microweld route first

Posted: Thu Mar 20, 2014 5:21 pm

Author: ruffle

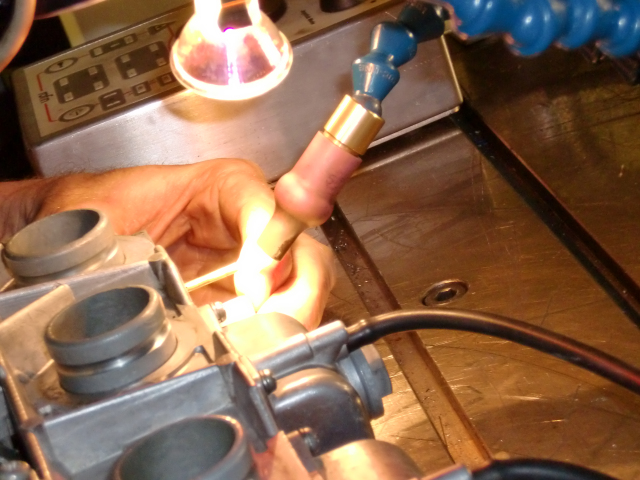

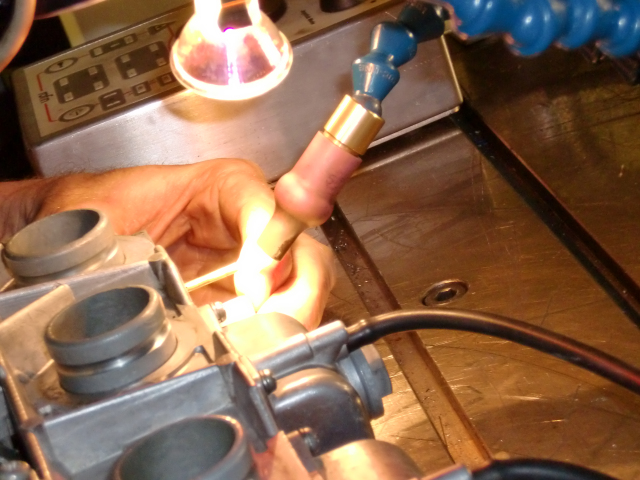

Well I tried the laser/micro welding. Went over to Carrs Welding in Kettering and they were really really helpful. The chap that wielded the welder, Alistair, is a biker so knew the score.

Here's the carbs on the machine with the broken bit being held in place by the welders finger. Apparently you rapidly learn not to put fleshy bits in the path of the laser... and if you do, it cauterises the wound automatically

The pink thingie is the laser and yes he was using a hair-thin filler rod but moved that out of the way for the picture.

Unfortunately it didn't work. The carb body had too much zinc and just popped, fizzed and fell apart under the laser. Alistair was sensible enough to say it wasn't going to work and stopped before any damage was caused.

Fortunately, the micro welding really is micro and the blowouts havn't destroyed it so I can fall back to plan B and try JB Weld marine epoxy which, according to JB Weld.co.uk, is impervious to fuel once cured.

I think I'll use a teensy amount on the joint and then epoxy an aluminium sleeve around the outside as under the microscope it's obvious that there are other cracks in that bit of the casting.

Just for my amusement, Alistair demonstrated the micro welding on a scrap bit of ally and produced a hair thin weld (I could hardly see it even with the bins on) that under the microscope looked just as good as any welding I've seen... except it was less than a millimeter wide

Impressive even if it doesn't work on 42 year old alloys of unknown composition.

Posted: Thu Mar 20, 2014 5:36 pm

Author: PAULJAC47

Tricky...how about making a sleeve that fits over the parts to be joined,could be machined to be shrink fit,heat it up and rely on contraction of metal to hold,some micro drillings and pins could be used to supplement if needed...

PaulJ

Posted: Thu Mar 20, 2014 5:53 pm

Author: ruffle

That was plan err... C?

Trouble is... the casting tapers by about 0.2mm (~10 thou for you imperialists) which makes sense I 'spose; that would help get it out of the mold.

A heat shrunk sleeve could end up being tight at the top and loose at the main jet end.

Posted: Thu Mar 20, 2014 6:15 pm

Author: PAULJAC47

Ok how about the end nearest the bottom making a couple of tabs that could be folded over to retain broken part,fill up" tube splint" with some araldite when its shrunk fitted before tabs bent....Paul J

Posted: Thu Mar 20, 2014 8:22 pm

Author: zed1015

I would make a little jig (bolt/washers etc) that goes up the centre of the carb and firmly holds the broken section in place.

Then cut an external thread over the casting so that a thin threaded sleeve can be fitted and loctited. This would fix it permanently and not be affected by fuel.

By using a split die the slight taper can be straightened in a couple of passes.

Obviously the brass tube in the float bowl will removed temporarily for the die to clear.

Posted: Thu Mar 20, 2014 8:49 pm

Author: Z1parR

Not surprised Alistair couldn't weld it , look at the depth of the lenses in his glasses

Posted: Fri Mar 21, 2014 10:28 pm

Author: Sha Hoorsur

Possibly the most stupid suggestion of all time, but, if the metal has such a high zinc content, will it not solder?

Posted: Fri Mar 21, 2014 10:43 pm

Author: Mark Tiller

Sha Hoorsur wrote:Possibly the most stupid suggestion of all time, but, if the metal has such a high zinc content, will it not solder?

Bakers fluid would help it take

Posted: Mon Mar 24, 2014 10:42 am

Author: ruffle

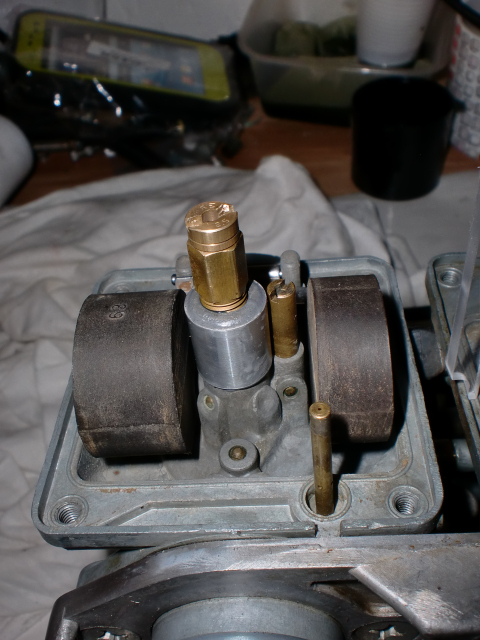

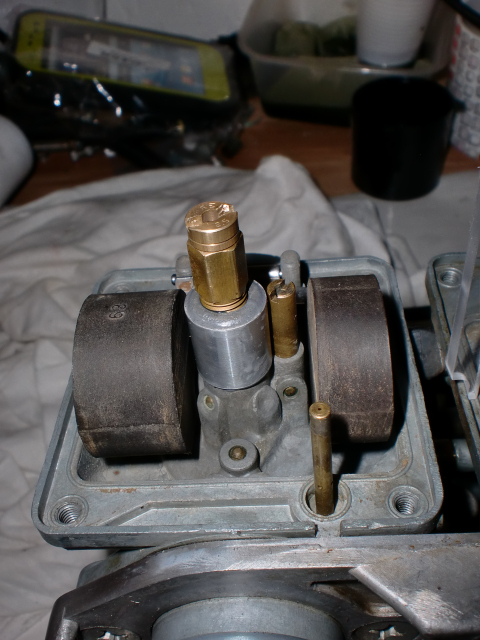

After all the suggestions (and many thanks for the ideas) I went with the epoxy and sleeve method.

I first epoxied (using JB Weld marine epoxy which, according to the man at JB Weld.co.uk is fine with petrol once cured) the broken bit of the casting back on using the teensiest end-of-a-cocktail stick amounts of gloop.

Then I turned up a sleeve with about 0.5mm clearance at the top (bottom as you look at the picture), spread a thin layer of epoxy on the carb and more in the sleeve before pushing it on in the hope that an all-over layer of epoxy would reinforce the other cracks in the casting.

Time will tell if the man from JB Weld.co.uk is telling the truth

).

).