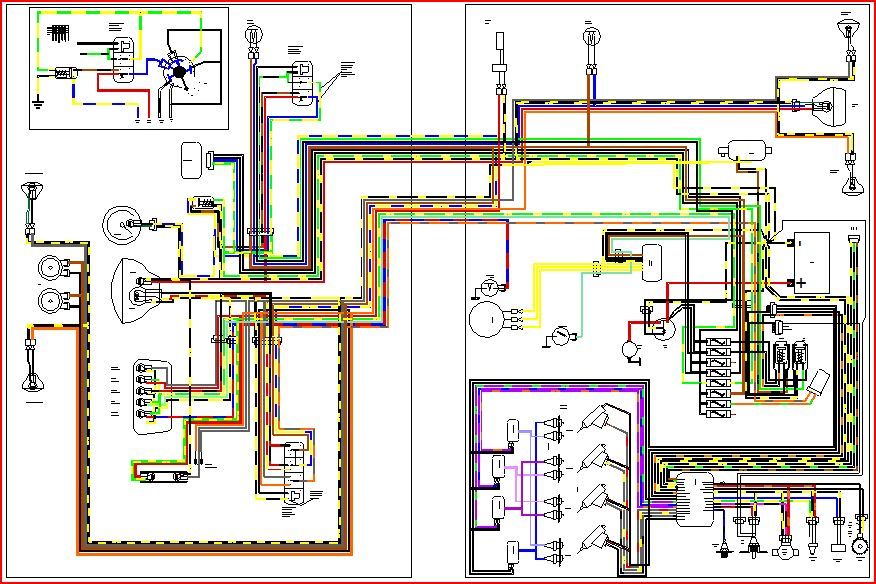

I'm going to start making a custom loom (pictured below) for my Z800 build and need to know what gauge cable to use for each part. I'm using an M-Unit to control electrics and the ring terminals are quite small on it.

If someone could fill in the blanks as below, I'd be much obliged:

Headlamp Relay to Headlamp = 6mm / 20amp

So here is the list, grouped into sub looms:

STARTER CIRCUIT

1) Starter Switch to M-Unit =

2) Starter Switch EARTH =

3) M-Unit to Starter Relay =

4) Starter Relay to Starter Motor =

5) Battery to Starter Relay =

6) Starter Motor EARTH =

7) Starter Relay EARTH =

8) M-Lock Immobiliser = SUPPLIED

9) M-Lock Immobiliser EARTH =

LIGHTS

1) Headlamp switch to M-Unit =

2) M-Unit to Headlamp =

3) Headlamp EARTH =

4) Brake Switches to M-Unit =

5) M-Unit to Brake Light =

HORN

1) Horn Switch to M-Unit =

2) M-Unit to Horn =

3) Horn EARTH =

IGNITION CIRCUIT

1) Dyna-S = INCLUDED

2) M-Unit to Coils =

3) Reg/Rect to Coils / Dyna-S =

CHARGING

1) Reg/Rect to Battery =

2) Reg/Rect to Dyna-S =

3) Reg/Rect EARTH

Also, should all earths go to the same point on the frame or should I spread them out to shorten cable runs?

Many thanks in advance…