Page 1 of 2

helicoils

Posted: Fri Nov 25, 2011 5:19 pm

Author: sme

what size of helicoil is needed for the cam caps ,

the bolts that screw into the head ?

any tips on using them?

Posted: Fri Nov 25, 2011 5:24 pm

Author: Pigford

Ginger Bear has some experience with these little beasties

Posted: Fri Nov 25, 2011 5:25 pm

Author: Ginger Bear

M6 are what you need, I would recommend 'Time serts' personally....... Far superior, in my opinion.

I'll try & dig out a bit more info.

Posted: Fri Nov 25, 2011 5:27 pm

Author: Pigford

..that was quick

Posted: Fri Nov 25, 2011 5:46 pm

Author: Ginger Bear

Posted: Fri Nov 25, 2011 8:28 pm

Author: sme

where can i buy these?

is it a case of drilling a bigger hole and threading it then insert the time sert?

Posted: Fri Nov 25, 2011 8:40 pm

Author: Ginger Bear

Posted: Fri Nov 25, 2011 9:24 pm

Author: kev edwards

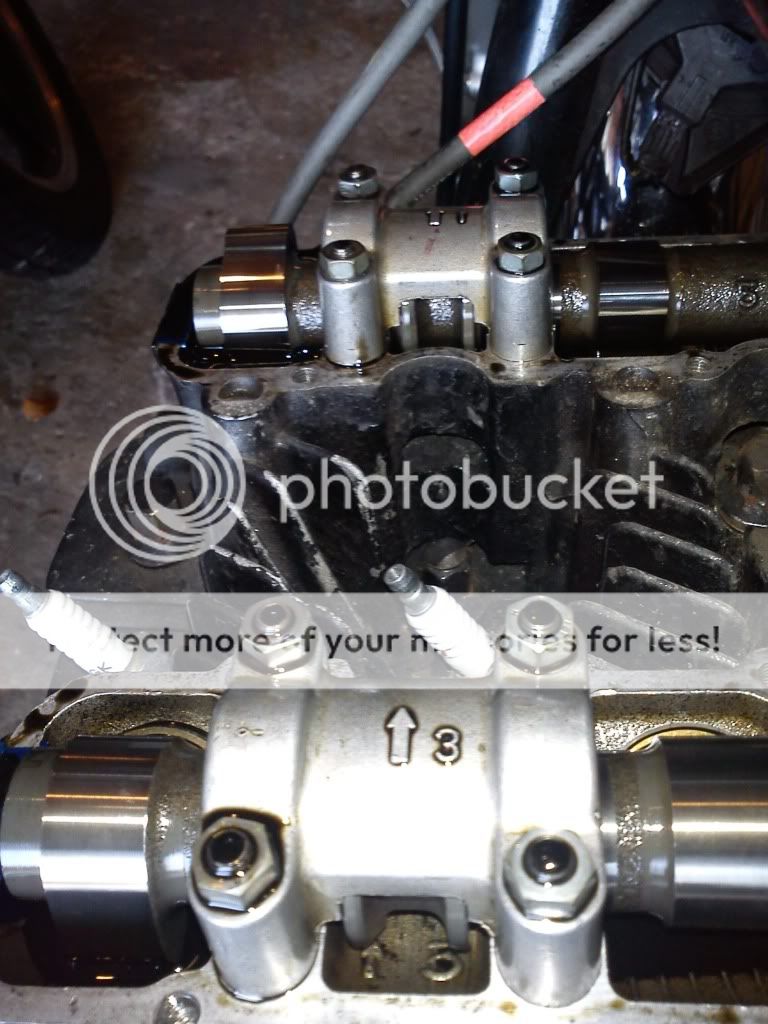

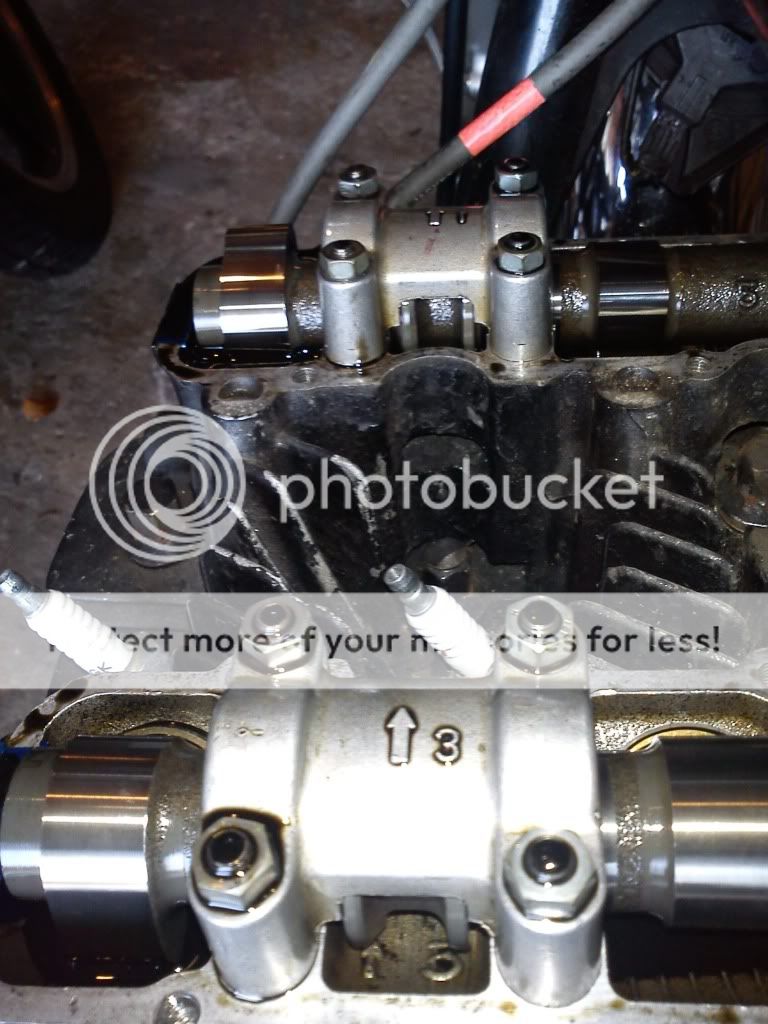

This was my answer 5 years ago and it,s still going strong, getting the cams in is a wiggle, i do not have the bike anymore, but another site member has it and is still enjoying it.

the first set i made on a pillar drill, and i believe are still in the bike i made more on a lathe but have since thrown them away.

Posted: Sat Nov 26, 2011 3:31 pm

Author: hanskloss

I did a cheap fix with M7 bolt, does not require head drilling just cut the M7 thread in M6 one, had to drill the cam cap, more difficult if the broken thread is with positioning pin as it has to be drilled through too, but done thais as well

Posted: Sat Nov 26, 2011 4:42 pm

Author: Ginger Bear

sme wrote:

is it a case of drilling a bigger hole and threading it then insert the time sert?

That's exactly how it's done, same process for helicoils too.

Most kits come with oversize drill bit, tap & insertion tool.

Posted: Sat Nov 26, 2011 5:41 pm

Author: Mark Stratton

Kev every time the issue is raised about cam cap bolt threads I have always thought that it must be possible to use a stud which must be far superior in strength than an aluminium thread. Your solution proves it.

I am going to take my head to Ray Debben for some work later and was going to ask if he could sort the cam cap threads whilst it is having the other work done but your solution looks best to me. Is it easy to have the studs made and do you have the sizes. I have a mate with a lathe who is always offering his services free of charge so i might just give him a try.

Sorry sme didn't mean to hijack your thread.

Posted: Sat Nov 26, 2011 5:50 pm

Author: Rich

If you are going for high lift cams you will not get the cam caps on with studs that length

Posted: Sat Nov 26, 2011 5:54 pm

Author: Pigford

Rich - you could if you used Al's special "cam compressor" tool

Posted: Sat Nov 26, 2011 8:55 pm

Author: kev edwards

Mark Stratton wrote:Kev every time the issue is raised about cam cap bolt threads I have always thought that it must be possible to use a stud which must be far superior in strength than an aluminium thread. Your solution proves it.

I am going to take my head to Ray Debben for some work later and was going to ask if he could sort the cam cap threads whilst it is having the other work done but your solution looks best to me. Is it easy to have the studs made and do you have the sizes. I have a mate with a lathe who is always offering his services free of charge so i might just give him a try.

Sorry sme didn't mean to hijack your thread.

Mark/ Sme, it's a piece of piss to do, i will look to see if i have any of the studs left as i made extra sets and never got round to replacing the first set i put in, there are two different ones because the locating dowels still have to be retained, but they are a stock ht 8mm stud centered on the lathe and turned to 5.9mm to suit which holes they go into, then a pilot drill is used in the head to suit an 8mm taps which were slightly ground to give a small clearence in the holes with the locating dowells these were then fitted to the head, the ones going where the dowells are are slightly ground like the taps, the studs are machined back enough so they are slighgtly beneath the dowell shouder whiich is where the thread starts and beneath the the face where the camcaps fit, cam caps are then fitted and the studs measured to length allowing for the nut and a thin serated washer, the cam cover has to have a little machined out of it where the studs are as it's a very close fit, i did this with a router as i had no access to a mill, as said getting the cams in is a bit of a wiggle and high lift cams a bit more of a wiggle, easy enough even for a man with M.E. . I remember this time well as i came under a lot of flak from people on this site and a former journo when i tried to sell caps on ebay, i at the time extended an invite to the journo to come and see what can be done, but he declined, i have also made another style of insert with the dowell as an integral part of the insert for another club member abroad who is very happy with the results, in these times when heads and assosiated parts get harder to find we will have to think outside of the box to keep these bikes running and on the road.

Hope this helps anyone who runs into these problems and also has to operate within a very tight budget.

Posted: Sat Nov 26, 2011 9:38 pm

Author: nanno

I used helicoils on my first Z1000J head (right after I bought the bike) and switched to timeserts (because I received a set for a very tempting price) when doing my "new" i.e. overhauled head.

In reality the timeserts look a lot beefier, but judging from the amount of force possible to be sustained by the threads, there isn't much of a difference or in other words: with both solutions, you will first squash the cam-cap-bearing-shells, before you pull out the thread repairs. The helicoil let go slightly earlier, but way beyond 40 NM, which was about 3 time the recommended torque (which is 15NM IIRC).

So both will be fine, timeserts look more sturdy though.

Cheers,

Greg

the first set i made on a pillar drill, and i believe are still in the bike i made more on a lathe but have since thrown them away.

the first set i made on a pillar drill, and i believe are still in the bike i made more on a lathe but have since thrown them away.