Hello Guest User,

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

copper head gasket sealing

Moderators: KeithZ1R, chrisu, paul doran, Taffus

copper head gasket sealing

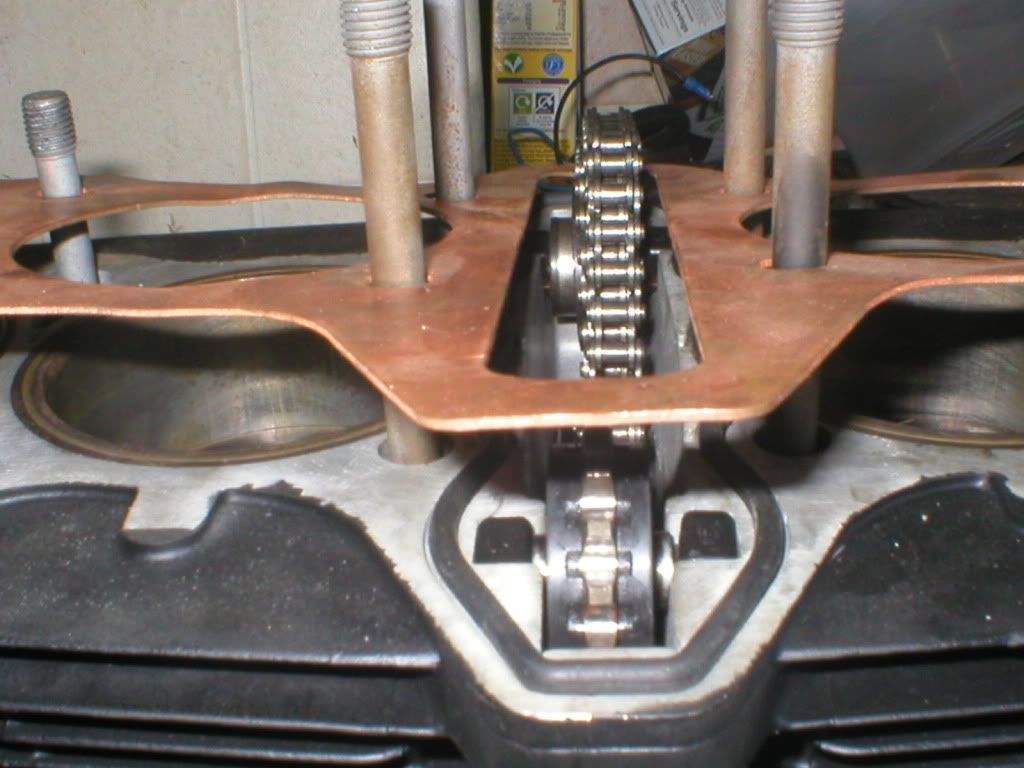

i was just going to put my cylinder head on my engine and came upon a minor thing,which is,my barrels have been piano wired,and the head gasket is copper,now the problem i see is,theres a run for a rubber seal around the cam chain hole ,when i put the rubber seal in it seems to be protruding a bit much,and to get a seal on the wire with the copper gasket , i would have to tighten the head down very much.  any info would be a bonus.

any info would be a bonus.

push me shuv you.sez who sez me.

owing p.u.m. (76 z1b)(v reg z1r)

owing p.u.m. (76 z1b)(v reg z1r)

-

Steve Cooke

- Hardcore

- Posts: 1612

- Joined: 18th Mar 2007

- Location: Southampton

-

Steve Cooke

- Hardcore

- Posts: 1612

- Joined: 18th Mar 2007

- Location: Southampton

- ade woollams

- Custard Cream

- Posts: 505

- Joined: 5th Mar 2007

- Location: within the smoke n the burnout zone

hillbilly .

go to b&q get a clear silicon cartridge and gun.fill in the groove and then lightly smear over the surface of the block where the gasket will sit .now the most important part of this is not to get it to close to the rear outside pins as they are oil ways and you dont want to fill those up when you pull the head down .

lower the gasket onto this and then do the same again also putting a bead of the stuff around the cam chain tunnel .then fit the head .hope this helps good luck..

go to b&q get a clear silicon cartridge and gun.fill in the groove and then lightly smear over the surface of the block where the gasket will sit .now the most important part of this is not to get it to close to the rear outside pins as they are oil ways and you dont want to fill those up when you pull the head down .

lower the gasket onto this and then do the same again also putting a bead of the stuff around the cam chain tunnel .then fit the head .hope this helps good luck..

dragracing, because it takes more than one ball !!!!!!!!!!!!!!!

http://www.youtube.com/watch?v=pNoktjNP ... ture=share

http://www.youtube.com/watch?v=pNoktjNP ... ture=share

One thing to add is that you may experience a little oil weeping from the oilways around the outer studs on initial fire-up.

This is because the piano wires have to be (highly) compressed into the copper head gasket before the mating surfaces of the block and head have chance to make contact with the copper gasket.

The best way, to my own personal experience, is after max torquing the cyl head nuts, initially run the engine for no more than 60 seconds, then immediately re-torque the head down again whilst the copper gasket has annealed (softened) a little.

After looking at your pics, am I right in thinking you are still using the standard waisted cyl studs.? My guess is if you're running a solid copper head gasket then you're running high cylinder pressures due to either high comp pistons or a blower.? Either way I would expect the requirement for higher cyl head torque figures - something that the standard waisted studs can not sustain. Debbens can provide APE heavy duty cyl studs & nuts. I would also make sure you fit new head/stud washers too.

Regs, Will.

This is because the piano wires have to be (highly) compressed into the copper head gasket before the mating surfaces of the block and head have chance to make contact with the copper gasket.

The best way, to my own personal experience, is after max torquing the cyl head nuts, initially run the engine for no more than 60 seconds, then immediately re-torque the head down again whilst the copper gasket has annealed (softened) a little.

After looking at your pics, am I right in thinking you are still using the standard waisted cyl studs.? My guess is if you're running a solid copper head gasket then you're running high cylinder pressures due to either high comp pistons or a blower.? Either way I would expect the requirement for higher cyl head torque figures - something that the standard waisted studs can not sustain. Debbens can provide APE heavy duty cyl studs & nuts. I would also make sure you fit new head/stud washers too.

Regs, Will.

Kawasaki H2C 750, ZRX1100R, H**** VF1000RG Rothmans, H**** VF500F2F, Suzuki GSXR750F Slabbie

cheers for the replys ,will ,i dont think it will be running over 10.5.1 .i have read somewere that the standard studs will tolorate that number ,i just have to torque them down properly.its just a 1197cc kit that ive put on,if i go any sillier then i will have to change them.

push me shuv you.sez who sez me.

owing p.u.m. (76 z1b)(v reg z1r)

owing p.u.m. (76 z1b)(v reg z1r)

I would change them, the ape studs and nuts are not that much and you can torque them down much harder, from memory 45 ft lbs compared to stock 25 ft lbs.

You may get away with stock studs at 10.5 to 1 although I would not try, but I dont think you will get away with that CR and copper head gasket, for what they cost its got to be a worth while investment!

I would not use silicone from B and Q either.

Is your Crank welded?

You may get away with stock studs at 10.5 to 1 although I would not try, but I dont think you will get away with that CR and copper head gasket, for what they cost its got to be a worth while investment!

I would not use silicone from B and Q either.

Is your Crank welded?

To stop any chance of oil leaks from the back studs when using the copper gasket you should really (dry block). Plug the feeds from the main oil gallery and in the head and fit a direct top end oiling kit as can be seen on my Drouin project. Are you going to race this coz if not why aren't you using a cometic fibre one as the copper ones are usually only used for regular strip downs in race situations as they come apart clean for reuse.

-

kev edwards

- Hardcore

- Posts: 1487

- Joined: 3rd Apr 2009

- Location: leverington UK

im using a copper gasket so if i strip the motor ,i can put it back on again,plus ive had the crank welded,so its nearly a silly build motor,i maybe take it down the strip sometime,just to see what it will do,  maybe employ an experianced one to take it down for me,

maybe employ an experianced one to take it down for me,  any offers.

any offers.  i havent took the studs out and put upgrade ape ones in,as with my luck,i would snap the last one off and be stuck with more time without a ride,an to tell the truth its been in bits for about 6 years,and its about time it was back on road

i havent took the studs out and put upgrade ape ones in,as with my luck,i would snap the last one off and be stuck with more time without a ride,an to tell the truth its been in bits for about 6 years,and its about time it was back on road

push me shuv you.sez who sez me.

owing p.u.m. (76 z1b)(v reg z1r)

owing p.u.m. (76 z1b)(v reg z1r)

Who is online

Users browsing this forum: No registered users and 19 guests