Hello Guest User,

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Please feel free to have a look around the forum but be aware that as an unregistered guest you can't see all of it and you can't post.

To access these 'Registered Users Only' areas simply register and login.

Caliper Bleed nipple leaking.

Moderators: KeithZ1R, chrisu, paul doran, Taffus

Caliper Bleed nipple leaking.

Any suggestions on getting a brake bleed nipple to seat properly?

Some googling suggested recutting the seat using a bored out nipple as a guide; but that means a) knowing the correct angle of the seat and b) grinding a drill to that angle. Anyone know the seat angle for a standard Z nipple (43085-001) ?

Another suggestion was to cut the threads off an old nipple and then use it as a plug with some grinding paste on the end to clean up the seat.

Any other ideas?

Some googling suggested recutting the seat using a bored out nipple as a guide; but that means a) knowing the correct angle of the seat and b) grinding a drill to that angle. Anyone know the seat angle for a standard Z nipple (43085-001) ?

Another suggestion was to cut the threads off an old nipple and then use it as a plug with some grinding paste on the end to clean up the seat.

Any other ideas?

Had the same problem myself once,i took the nipple out and ground a drill tip to the same angle as the tip of the nipple,then just carefully drilled the nipple hole a touch,replaced nipple and all was fine.

Check theres no muck in the nipple seat first,also may be worth trying a new bleed nipple too, before you go down the drilling route.

Check theres no muck in the nipple seat first,also may be worth trying a new bleed nipple too, before you go down the drilling route.

Cat3 - I can't see any signs of a crack. Someone's obviously had problems with a sheared nipple in there at some time as there's slight diagonal score mark across the hole left from a hacksaw blade or somesuch.

Peering down the hole with a jewellers loop and a torch the seat looks a little 'gaulled'. The fluid's also coming out of the hole in the nipple and not from around the threaded hole; hence my thinking it's the seat.

bart - glad to hear someone else has re-cut the seat with success (yes I have tried a brand new nipple). How did you go about getting the drillbit to the same angle as the nipple? Skill, eyesight and talent? or by some means that can be employed by an engineering muppet like me :-) ?

Peering down the hole with a jewellers loop and a torch the seat looks a little 'gaulled'. The fluid's also coming out of the hole in the nipple and not from around the threaded hole; hence my thinking it's the seat.

bart - glad to hear someone else has re-cut the seat with success (yes I have tried a brand new nipple). How did you go about getting the drillbit to the same angle as the nipple? Skill, eyesight and talent? or by some means that can be employed by an engineering muppet like me :-) ?

Fair do's Ruffle.

The best way to line a drill up with the hole is to screw in a correct size tap first in the bleed nipple hole. Then clamp the shank of the tap in the chuck of a pillar drill. Then clamp the caliper, somehow !, in that position.

With it all locked in position you then release the chuck from the tap, unthread the tap from the caliper & then insert you chosen drill with the correct angle on & drill ! You now know the drill is centred exactly with the hole.

The best way to line a drill up with the hole is to screw in a correct size tap first in the bleed nipple hole. Then clamp the shank of the tap in the chuck of a pillar drill. Then clamp the caliper, somehow !, in that position.

With it all locked in position you then release the chuck from the tap, unthread the tap from the caliper & then insert you chosen drill with the correct angle on & drill ! You now know the drill is centred exactly with the hole.

http://www.ebay.co.uk/itm/M10-x-1-25-ba ... 256bea582b

Hi if looks are not important just fuction, i did have some success with adapting one of these just depends on what caliper you have it would be poss to drill out existing niplle thread oversize and poss fit a shortened adapted one of these just a thought!!Paul J

Hi if looks are not important just fuction, i did have some success with adapting one of these just depends on what caliper you have it would be poss to drill out existing niplle thread oversize and poss fit a shortened adapted one of these just a thought!!Paul J

PAULJAC47,,,,,"She may not look like much, but she's got it where it counts, kid."

-Han Solo

You can't polish a turd, but you can roll it in glitter

Salad is what real food eats.

Anon

PUM 673

-Han Solo

You can't polish a turd, but you can roll it in glitter

Salad is what real food eats.

Anon

PUM 673

Thanks for that - useful tip for lining up the drill bit.

Still puzzled as to how I determine the seat angle though.

I have a 'Drill Doctor' that can grind drills to a selection of pre-set angles but my old school protractor isn't up to measuring the end of the bleed nipple (there's not a lot to measure from )

)

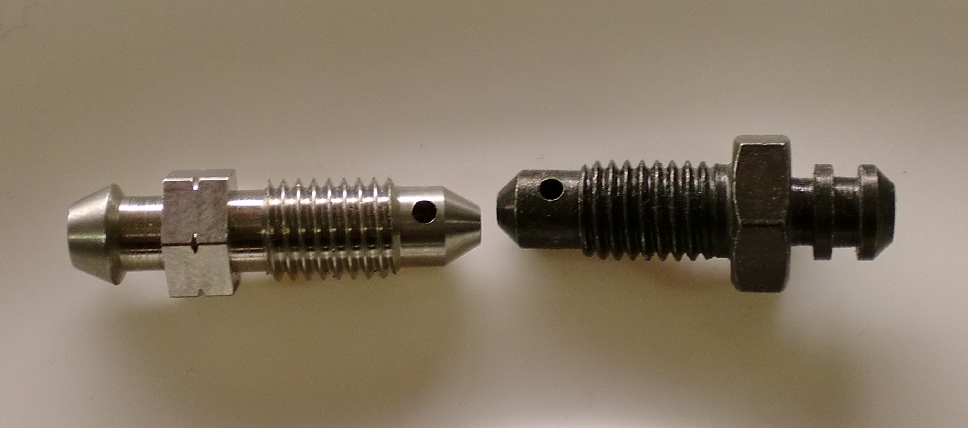

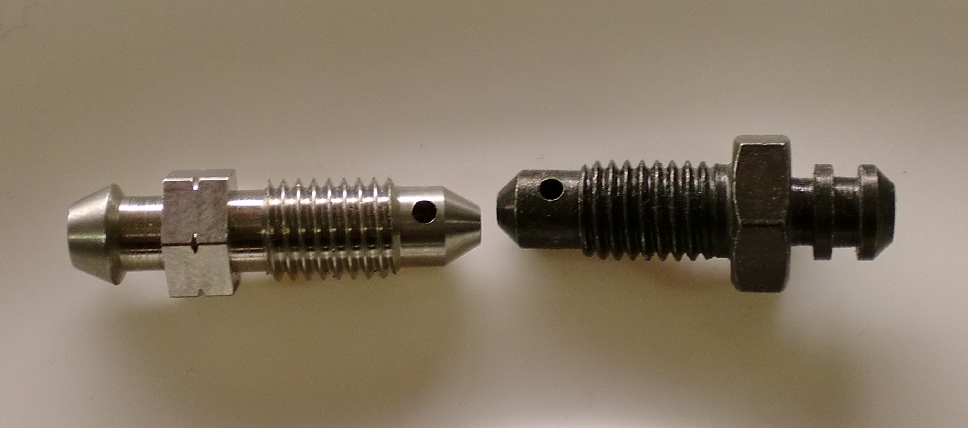

Is there a standard angle for these things? I can't think why Kawasaki would have select a weird number but comparing it to a brembo one the angle looks different (the Brembo's on the left).

Still puzzled as to how I determine the seat angle though.

I have a 'Drill Doctor' that can grind drills to a selection of pre-set angles but my old school protractor isn't up to measuring the end of the bleed nipple (there's not a lot to measure from

Is there a standard angle for these things? I can't think why Kawasaki would have select a weird number but comparing it to a brembo one the angle looks different (the Brembo's on the left).

Hmmmm..... doing more Googling and there are lots of folk selling bleed nipples and while they make references to the thread pitch and diameter, nobody seems to mention the seat angle.

Perhaps it is a standard and it's just my eyes fooling me into thinking there's a difference between the two in that picture.

Anyone know?

Perhaps it is a standard and it's just my eyes fooling me into thinking there's a difference between the two in that picture.

Anyone know?

Clamp the nipples side by side in a vice hold straight edge on each together, further away on the straight edge the difference in angle if any will be more apparent...Paul J

PAULJAC47,,,,,"She may not look like much, but she's got it where it counts, kid."

-Han Solo

You can't polish a turd, but you can roll it in glitter

Salad is what real food eats.

Anon

PUM 673

-Han Solo

You can't polish a turd, but you can roll it in glitter

Salad is what real food eats.

Anon

PUM 673

Ruffle,when i ground the drill i held the drill tip up against chamfered end of the nipple,like the photo you have just posted with the two nipples end to end so the angled part of the drill tip is touching the angled piece of the nipple,when the drill is ground to the correct angle the drill and nipple will be in a straight line,If you can understand my description

Well.... that very nearly worked (

The seal with the nipple nipped up was almost there; but a final tweak (admittedly more than I'd normally give a brake nipple) overloaded the iffy old thread in the caliper and I got that nasty 'Ooops - there goes the thread' feeling

Ummmm.... anyone got a Z1-R left front caliper?

The seal with the nipple nipped up was almost there; but a final tweak (admittedly more than I'd normally give a brake nipple) overloaded the iffy old thread in the caliper and I got that nasty 'Ooops - there goes the thread' feeling

Ummmm.... anyone got a Z1-R left front caliper?

Who is online

Users browsing this forum: No registered users and 18 guests