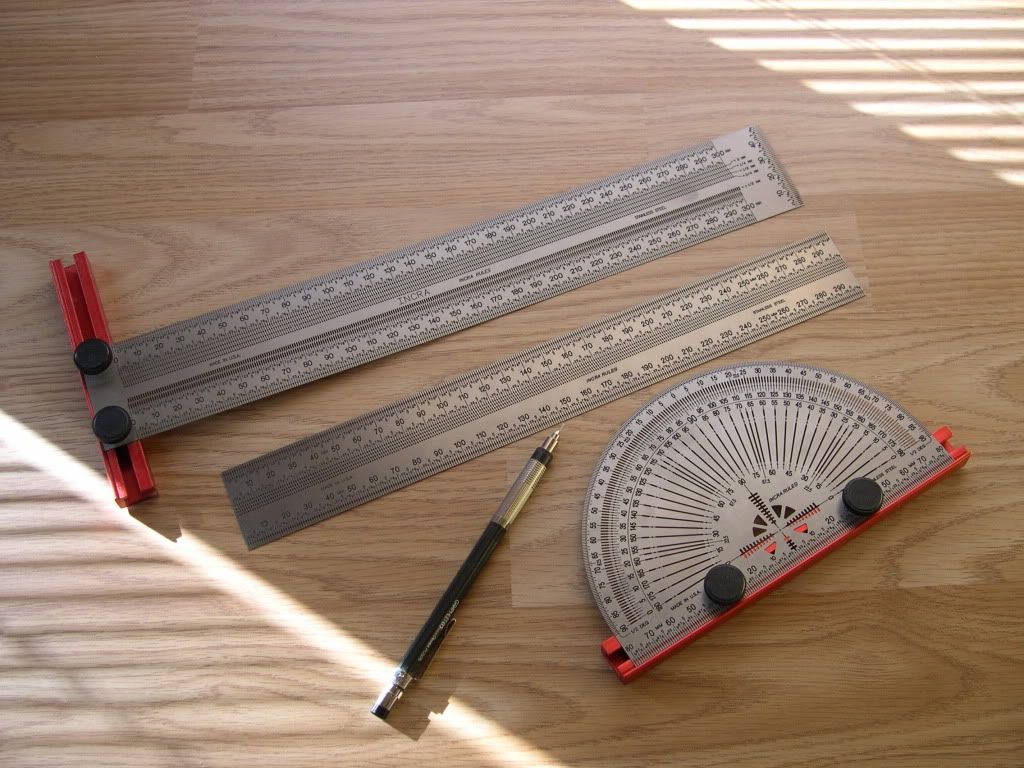

I got a set of these Incra rules. I find them very useful- perhaps you will too.

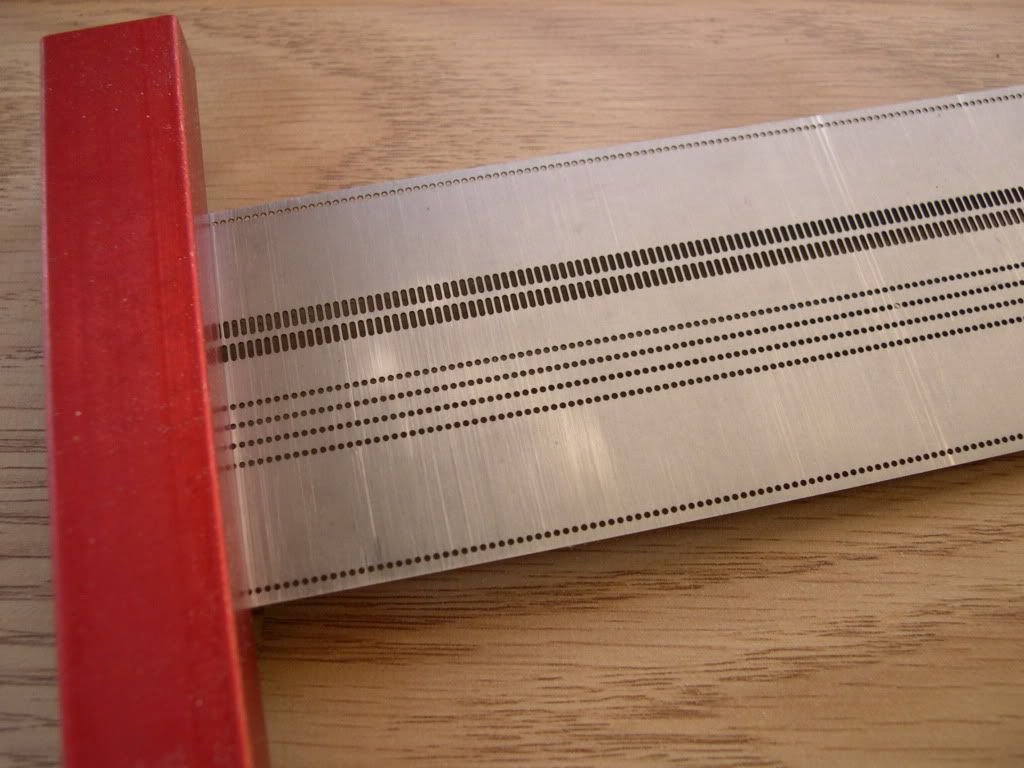

They are a set of thin stainless rules- they are etched with the measurements but they are also etched right thru at each incrament- thus you can poke your pencil thru these holes to make your mark.

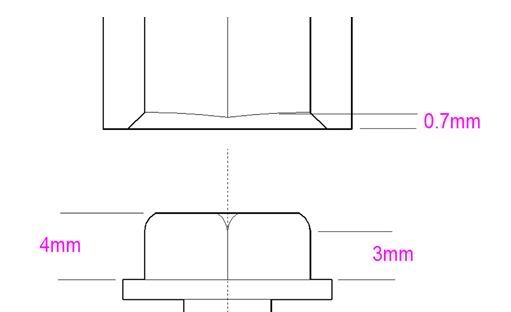

You have to use a 0.5mm pencil.

They make marking out very easy and accurate.

On the rear its easy to see all the holes

With the red end stop in place the rule can be dragged along to make a line parallel to the edge.

Using two pencils these rules can be used to easily draw circles and arcs.